Rayonier 2022 Sustainability Report: Safety

Safety is a way of life at Rayonier and one of the cornerstones of our culture. It is embedded within every action we take and guided by a fundamental respect for people.

Originally published on Rayonier.com

Our Senior Leadership Team and Board reinforce the importance of maintaining a strong safety culture. Our guiding principle is that all of our employees and contractors should return home safely each day. We believe that nearly all accidents are preventable, and we encourage our employees and contractors to challenge unsafe behavior with a zero-tolerance mindset. We take steps to help our employees feel comfortable raising any safety-related concerns, and we do not tolerate retaliation against teammates or contractors who report suspected violations. Leadership of our U.S. safety program resides with the Director of Health & Safety, who reports directly to the Executive Vice President & Chief Resource Officer. Leadership of our New Zealand safety program resides with the Director of Health & Safety, who reports directly to the Managing Director, Rayonier Matariki Forests.

NEW ZEALAND

In New Zealand, workplace safety is regulated by the Health and Safety at Work Act 2015, and our comprehensive safety management program includes both employees and contractors pursuant to local laws. We are proud to have 100% of our eligible New Zealand contractors Safetree™ certified by the New Zealand Forest Industry Safety Council (FISC). In 2022, we focused on reinforcing the “start when certain” approach; health and safety systems, processes, and technology; and improving the driving experience for log truck drivers.

“Start when certain” approach

In 2022, we created a Health & Safety Advisor position and appointed an existing employee with the requisite skills. The new role is primarily focused on contractor and operations facing activities. With this resource in place, we began a series of critical risk activity reviews. Through the team’s collaboration with our contractors, we have released an updated repair and maintenance safe system of work manual and are reviewing our tree felling safe work requirements. These initiatives continue to reinforce our “start when certain” approach to safe work practices.

Health & safety systems, processes, and technology

We continue to identify opportunities for improvement with our current systems and processes. A key focus has been on deploying a mobile app in New Zealand to support in-field entry of information, which will improve the efficiency of incident reporting. Implementation of the app is expected to be complete in 2023.

Additionally, in 2022, we commissioned an external audit of our health and safety management system with the objective of identifying compliance vulnerabilities and improvement opportunities. No compliance issues were identified, and the process provided us with useful insight and direction on areas for improvement. One improvement opportunity was exposure to a critical risk roadmap. While the roadmap reconfirmed we are on the right track, it also provided a helpful nine-point framework to define critical risks, focus stakeholders’ attention, and embed risk mitigation controls. We will apply this framework as we review our critical risks and safe work procedures.

Improving the driving experience for log truck drivers

Due to a disproportionately high representation in accident statistics, we internally identified log transportation as a critical area of focus in New Zealand. To gain an understanding of how drivers rated various aspects of work in our forests, we rolled out a survey to our thirdparty log truck drivers. This survey resulted in several projects including, but not limited to, finding ways in which we can support increased operational flexibility, providing more timely responses, distributing action reports around at-risk infrastructure, and strengthening our systems to help drivers receive timely information about in-forest elevated risk situations. We also encourage drivers to report situations in need of our attention, such as loadout setups and road access infrastructure.

UNITED STATES

Contractors perform several critical functions for Rayonier including timber harvesting, log hauling, site preparation, and replanting. Unlike in New Zealand, regulations incorporating contractor safety do not exist in the U.S. As a result, we have taken proactive steps to promote safe work practices among our contractors. Specifically, we have implemented a program with our U.S. contractors to facilitate better communication and education regarding safe work practices. While the program initially focused on building trust and strengthening relationships with contractors to establish an open dialogue about safety issues, we have continued to build on it over time. The program now includes safety alerts, a greater number of tailgate meetings on safety topics, education on best management practices, and our contractor safety near miss/ incident reporting program.

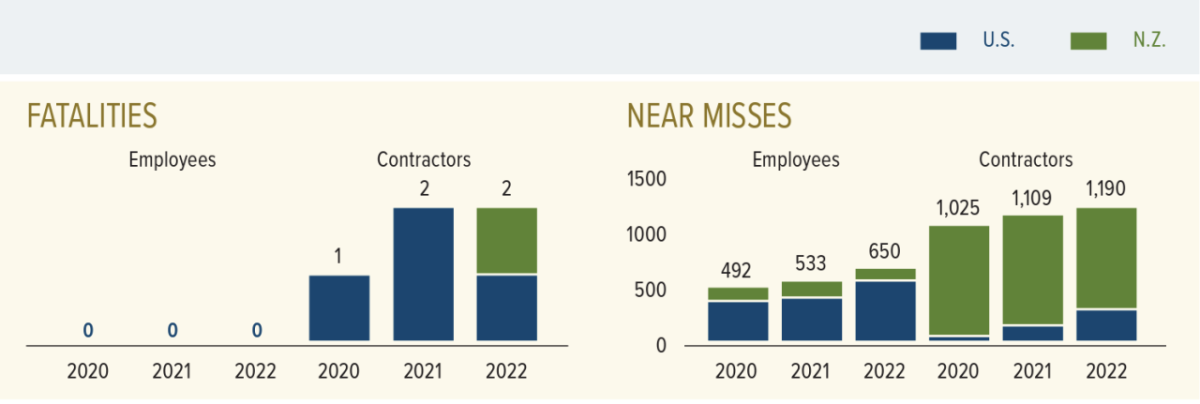

In 2022, we added safety-focused personnel, held 15 in-person OSHA training sessions throughout our U.S. operating areas, and dedicated additional resources to work with contractors unable to attend the scheduled events. Over 600 contractors attended the in-person training events, which focused on providing our contractors with tools and guidance to build out and enhance their own safety programs. Overall, this initiative was well-received by our contractors. Encouragingly, there was a 50% year-over-year reduction in recordable injuries across our U.S. contractor workforce. We view this as significant progress towards our goal of raising the industry standard and are now requiring an active written safety program from all contractors. Unfortunately, there were still two contractor fatalities reported in 2022. In response to each fatality, we evaluated the situations surrounding the incidents and implemented action plans to highlight mitigation measures for the safety risks identified.

Moving forward, we are aiming to expand our safety-related metrics. Specifically in 2023, we have been working toward developing internal methodologies for calculating contractor hours worked, which will advance our safety reporting to include TRIR and Lost Time Incident Rate (LTIR) for our U.S. contractors.

50% YoY reduction in contractor recordable injury count

2021 14

2022 7

SAFETY STAR RECOGNITION PROGRAM

“Workplace health and safety is important for the well-being of both employees and the employer because human loss is immeasurable and intolerable.”

—Don Webb, Rayonier, Employee

Don Webb, Resource Unit Land Manager, was recognized as the Safety Star Employee of the Year. Don was recognized for his dedication to promoting a strong safety culture—his diligence for keeping coworkers informed about monthly tailgate meetings, his enthusiasm for researching topics to present at safety meetings, and his efforts to coordinate and conduct safety kick-off meetings with contractors.

“It costs more money to do the right thing, but we take care of our equipment because our employees are like family. You can replace or fix a tractor that has been in an accident. You cannot replace someone’s life.”

—Dillon Stratton, 3D Trucking, Contractor

Dillon Stratton, 3D Trucking, was named as the Safety Star Contractor of the Year. Dillon was recognized for the innovative camera and driver alert system he uses on log trucks for his company, 3D Trucking. Each of Dillon’s rigs has a camera facing out through the windshield and one looking back down each side of the truck. This helps his truckers stay protected and prevent accidents. In addition to taking video, the system records issues such as hard braking and speeding, which Dillon uses to coach his employees on safe driving techniques.

We believe that our collaborative approach to employee and contractor safety is translating to heightened safety awareness and improved safety performance. We emphasize the importance of raising safety-related concerns at every opportunity, while also reassuring employees and contractors that we will not tolerate retaliation against anyone who reports suspected violations or near-misses. Our U.S. employee and contractor near-miss submissions increased during 2022 by more than 30% and 80%, respectively, versus the previous year. While we're encouraged by the upward trend in near-miss submissions reflecting increased awareness and communication, we unfortunately saw an increase in our U.S. employee recordable injuries in 2022.

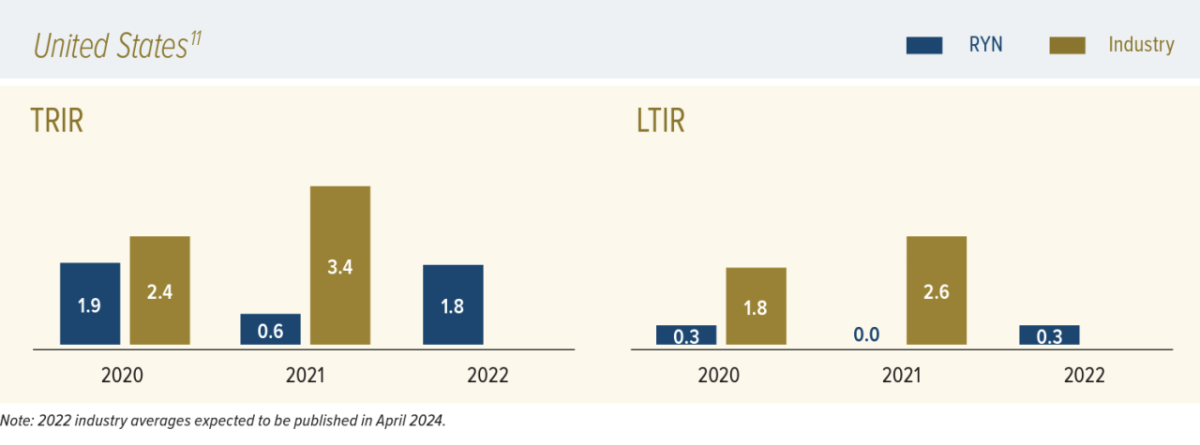

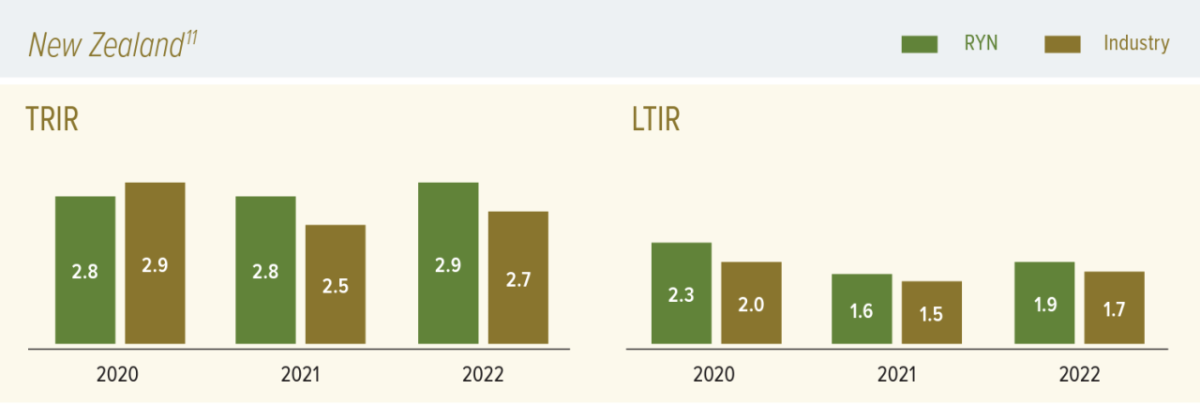

The charts above summarize our TRIR, LTIR, fatalities, and near misses in the U.S. and New Zealand over the last three years. TRIR and LTIR data covers employees in the U.S. and employees and contractors in New Zealand, whereas fatality and near-miss data covers both employees and contractors in the U.S. and New Zealand.

To learn more, view the full Rayonier 2022 Sustainability Report.