Suncor 2022 Report on Sustainability: Water Stewardship

Suncor 2022 Report on Sustainability

We believe water is a shared and precious resource that must be managed wisely.

Responsible energy development means satisfying industry’s water requirements while maintaining a healthy ecosystem and functioning water cycle for current and future generations. We strive to always raise the bar on company-wide water performance and water management practices.

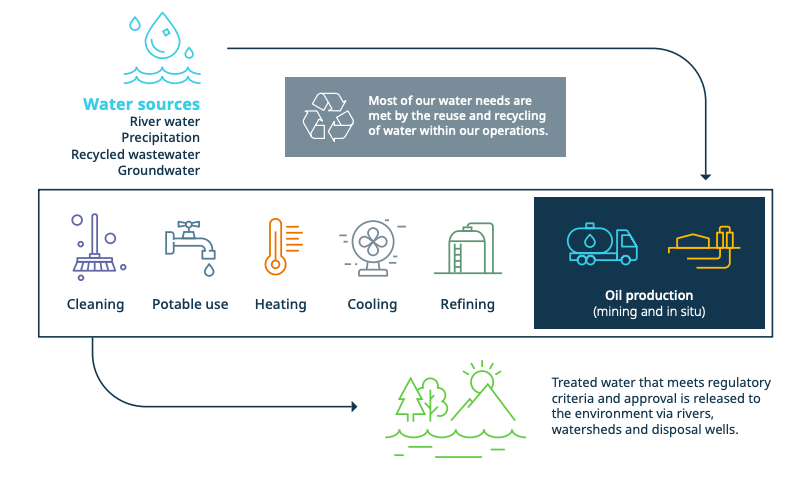

As water is an essential part of our operations, it’s important we find innovative ways to manage water effectively and efficiently across our business. This includes minimizing the withdrawal of fresh water from the watersheds where we operate; reusing, recycling and identifying opportunities to safely release water where possible; and safely storing water on our sites. The following principles guide our water management approach:

- Shared value of water

- Watershed management

- Reduce-reuse-release

- Integrated options analysis

Responsible water use is critical to the company, to neighbouring communities and to our stakeholders. It’s also crucial to achieving progressive reclamation and mine closure commitments.

Our internal issues management processes identify and help manage ecosystem, habitat and water-related risks and opportunities, including new or changing polices and regulations related to water.

Reduce-reuse-release

For our oil sands operations in the Regional Municipality of Wood Buffalo (RMWB), a holistic approach to water management is necessary for the sustainable development of oil sands mines and our continued commitments to closure and reclamation. This approach would allow our mining operations the opportunity to optimize water management and focus efforts on water use reduction, and the recycle, reuse, removal and release of treated mine water.

The ability to safely release water to the watershed is a critical component of an integrated water management approach. Water release is required to manage on-site water quantity and quality for all our operations. Storing mine water, which currently includes precipitation and runoff that comes into contact with our mining area on our sites, is not a sustainable long-term practice.

We are working with government, local communities and stakeholders to develop a policy and regulatory framework to safely release treated mine water from our oil sands sites. Integrated water management across the RMWB is key for oil sands water management and we are taking a collaborative approach to this work.

Technology and innovation

When it comes to advancing water-related technology, we continue to invest in research and technology development to increase efficiency (reduce and recycle) and optimize wastewater treatment. For example, we continue to reduce fluid tailings inventories at Base Plant through our holistic tailings management approach and permanent aquatic storage structure (PASS) treatment processes.

Pit lake technology mimics natural water bodies and is one of several solutions we are developing for water treatment. Choosing a technology for each site depends on the quality of water requiring treatment. Water quality differs based on factors such as the age of the mine and the type of ore and/or extraction process deployed. Our treatment focus is determined by the best available technology application and optimization of existing treatment options for our various sites and water types.

As we advance water treatment technologies, we’re sharing best practices and lessons learned with our industry peers through Canada’s Oil Sands Innovation Alliance (COSIA).

Monitoring

Environmental monitoring is critical, especially in measuring our effectiveness in water management. Our approvals require us to monitor our sites and assess ecosystem impacts in the watersheds where we operate. In addition to all of our site-specific monitoring, we also participate in the Oil Sands Monitoring (OSM) Program along with our oil sands peers, Indigenous communities and government stakeholders to conduct regional monitoring in the oil sands region of Alberta. The OSM Program began in 2012 and the oil sands industry provides $50 million annually to support the program’s activities. It is one of the largest regional environmental monitoring programs in North America and specifically focuses on tracking potential environmental impacts from oil sands facilities. The OSM Program also assesses potential cumulative environmental effects from oil sands development to help inform future monitoring, mitigation and management decisions.

Water performance

Mining

At our oil sands mines, our water management practices focus on minimizing Athabasca River water diversion, maximizing the recycling of process-affected water and minimizing the on-site storage of water. We continue to operate well below our annual water licences, withdrawing less water than we’re regulated to withdraw.

An operating site’s water performance is largely impacted by a facility’s design and configuration. Water performance at our mining sites in 2021 was mainly influenced by decreased annual precipitation rates in the Wood Buffalo region and increased water requirements for plant operations. In 2021, Base Plant freshwater consumption increased to 13.91 million cubic metres (Mm3 ). Freshwater consumption intensity increased by 9% to 0.12 m3 /BOE production at Base Plant. Fort Hills had relatively consistent absolute freshwater consumption year over year. Freshwater consumption intensity increased by 15% to 0.31 m3 /BOE production at Fort Hills due to decreased production, resulting from its singletrain operation in 2021. We will continue to explore opportunities to reduce water use.

At Syncrude, 2021 freshwater consumption totalled 36.85 Mm3 with an intensity of 0.36 m3 /BOE. Syncrude uses a monthly score card to track water use in order to identify opportunities for reducing withdrawal of freshwater from the Athabasca River. In 2021, conservation projects reduced withdrawal requirements by approximately 3.15 Mm3 . Approximately 85% of the water used in Syncrude’s plant operations was recycled from tailings facilities.

93% water recycle rates at Suncor’s Base Plant and Fort Hills mining operations

In Situ

The average water recycling rate at the Firebag and MacKay River in situ sites was approximately 99% due to operational efficiencies and site water optimization. Water at these sites is drawn from recycled wastewater from our oil sands upgrading and utilities operations, surface runoff water collected within the facility boundaries and from groundwater wells. In 2021, both Firebag and MacKay River increased freshwater withdrawal and consumption due to site ramp-up requirements and various site activities. The total in situ freshwater consumption intensity of 0.02 m3 /BOE in 2021 remained consistent with historic five-year performance. The amount of water released increased significantly, compared to 2020, to 3.03 Mm3 at Firebag due to operational requirements and the capacity at the site to receive water. Water release decreased at MacKay River due to more water being recycled or reused and because water was needed to restart the site after an unexpected operational incident in December 2019.

Refining and Logistics

Our refineries use fresh water for heating and cooling. All refineries have unique requirements and considerations based on the watersheds in which they operate. In 2021, relatively consistent downstream production, impacts from the pandemic and facility turnarounds led to similar freshwater absolute consumption and intensity values as 2020. We continue to explore and implement local initiatives that will result in more efficient water use, with less fresh water drawn from local water sources.

In 2021, approximately 39% of the total water used at the Edmonton Refinery was from recycled wastewater supplied from the Gold Bar Wastewater Treatment Plant in Edmonton.

None of our assets operate in areas where there is high risk of water stress. However, Suncor’s Commerce City refinery in Colorado operates in a region that is classified as moderate risk, where water supply curtailment would require bringing in water by pipeline or truck. We continue to monitor the status of the basin while focusing on implementing industry-leading innovation at our facilities to reduce, reuse and release water.

We are always looking for ways to limit the amount of water we use, including the amount of freshwater directly withdrawn from local water sources. One way we manage water at our refineries is by upgrading and maintaining the existing wastewater treatment facilities.

Exploration and Production

In our East Coast Canada operations, water is either produced offshore through desalination, or is transferred via vessel from St. John’s, Newfoundland. The Terra Nova floating production, storage and offloading vessel has been shut in since the end of 2019. In 2021, we restructured the Terra Nova project ownership and moved forward with the Asset Life Extension Project. We anticipate a safe return to operations before the end of 2022.

In 2021, both Suncor and Syncrude began reporting in accordance with the Mining Association of Canada’s Towards Sustainable Mining (MAC TSM) Water Stewardship protocol. This protocol is comprised of four focus indicators, which drive our performance: water governance, operational water management, watershed-scale planning and water reporting and performance indicators. All our mining operations achieved a AAA score for the watershed-scale planning indicator and an A score for the other three indicators in 2021.