Water Stewardship at Suncor- 2023 Report on Sustainability

We broke new ground when we first began publicly reporting our sustainability performance in the mid-1990s. Twenty-eight years later, our Report on Sustainability and its companion publication, the Climate Report, continue the practice of disclosing our progress in more than a dozen areas of environmental, social and governance (ESG) performance. Read more on our ESG progress in our reports here.

Effective water management is crucial to our business today and in the future.

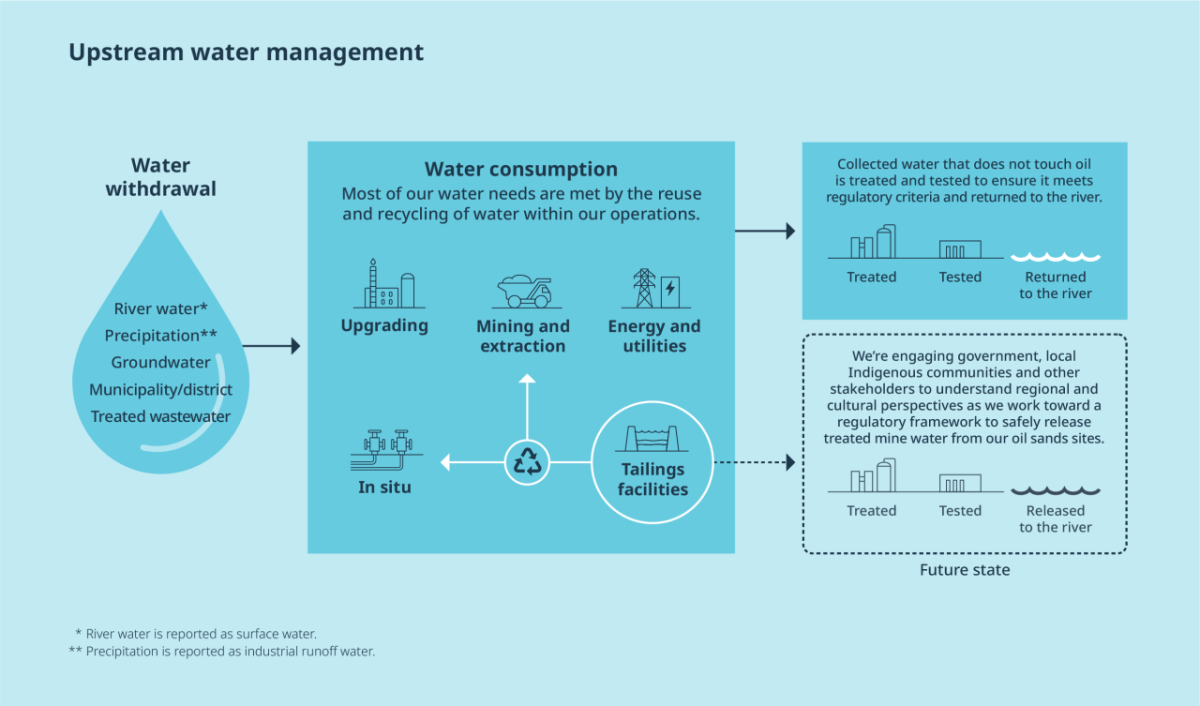

The Athabasca watershed has a deep cultural significance for the region’s Indigenous Peoples. We acknowledge its spiritual importance to community members and the understanding that the health of the rivers, landscape, wildlife and people are all interconnected. We believe in meaningful engagement that respects the unique and constitutional rights of Indigenous Peoples, including treaty rights and their deep connection with land and water. By continuing to learn about the rights, history, customs, beliefs, traditions and aspirations of Indigenous Peoples, we can apply this knowledge to our water management practices. This journey starts with the understanding that we all share the same aspiration for a healthy ecosystem. Water is an essential part of our operations so it’s important to effectively manage its use across our business. To date, these efforts include minimizing withdrawal of fresh water, recycling water and storing it safely. Even with these practices in place, we face a serious challenge in managing the volume of water currently stored on our mine sites. This includes water used in our extraction and production processes, precipitation and surface runoff that comes into contact with our mines. In addition to our efforts to reduce, reuse and recycle water, safely removing and returning treated water from our sites to the watershed is a necessary step to achieving progressive reclamation and mine closure. Working together with Indigenous communities, we will strive to identify solutions to achieve progressive reclamation and our mine closure outcomes and commitments.

Regulatory requirements

While we regularly submit updates of our reclamation and closure plans to the Alberta Energy Regulator, we are waiting for the federal and provincial governments to finalize the criteria for safely releasing treated water. Returning treated water is a global best practice used by municipal, commercial, industrial and agricultural sectors. Governments regulate water releases to protect the receiving waterbodies and downstream users. Other types of Canadian mines – including copper, nickel, iron ore, diamond and gold operations – have regulations to treat and release water used in their processes. The federal government is committed to developing these regulations for the oil sands by 2025. Having these regulations in place will allow us to restore and reconnect ecosystems in areas where we’ve operated. Our systems, combined with strict regulations, will ensure water can be safely released and protect the environment (fish, insects, birds, plants, animals) and downstream users. Once the criteria for releasing treated water are established, we can design treatment plans to meet these objectives. Regulations are key in our efforts to achieve our reclamation and closure plans, which require reducing the amount of water stored on site, avoiding the need to disturb more land for additional water storage and returning the landscape to a self-sustaining ecosystem. We will continue to work with governments, communities and stakeholders to develop the policy and regulatory framework to enable the safe release of treated mine water from our oil sands sites and reduce the need for more tailings facilities. Working together with Indigenous communities, we will work to identify water management solutions that respect their unique constitutional and treaty rights and acknowledge their deep connection with the land and water.

Our approach

- A holistic approach to water management is necessary to sustainably develop our oil sands mines and meet our commitments to reclaiming disturbed lands. This approach needs to consider all components of water management, including reducing, recycling, reusing and releasing treated mine water.

- Water at oil sands mines contains components such as sand, silt, clay, organics, salts, and a range of metals. These constituents are largely common to process water used in other types of mining and many other industrial activities. There is a wide range of proven technologies already in use in Canada and globally to treat process water so that it is safe for release.

- We have made significant investments in applying, adapting and testing different water management approaches and the effectiveness of various treatment processes and technologies on oil sands mine water to achieve levels safe for release to the environment.

- Every site is different and requires flexibility when choosing appropriate technologies for treatment. Our solutions for water management will continue to include reuse and recycling and where water release is appropriate, it will be protective of the environment and be considered with the input and knowledge of Indigenous communities.

Monitoring

Monitoring is critical for measuring the effectiveness of our water management processes. We are required to monitor water quality on our sites and assess ecosystem impacts in the watersheds where we operate. We also participate in the Oil Sands Monitoring (OSM) program along with Indigenous communities and government stakeholders to conduct regional monitoring. The OSM program is specifically focused on tracking potential environmental impacts from oil sands facilities. It also assesses potential cumulative environmental effects from oil sands development to help inform future monitoring, mitigation and management decisions.

Water performance

Mining

While our oil sands mines do not operate in a water-stressed region, our water management practices focus on minimizing Athabasca River water diversion, maximizing the recycling of process-affected water and minimizing the onsite storage of water. We continue to operate well below our annual water licences. Water consumption efficiency at our mining and upgrading facilities is largely affected by design and configuration. Water withdrawal often depends on the amount of annual precipitation. Suncor’s water withdrawal remained relatively consistent in 2022. In 2022, Base Plant decreased both freshwater consumption and intensity by 8% at 12.25 Mm3 and 0.67 m3 /m3 of hydrocarbon production respectfully. This is due to improved water management, along with more accurate tracking systems. Fort Hills’ freshwater consumption decreased by approximately 20% in 2022 to 8.52 Mm3 with an intensity of 0.90 m3 /m3 of hydrocarbon production as less water was required in the operation. At Syncrude, annual freshwater consumption totaled 39.87 Mm3, increasing by 8% due to higher production rates compared to last year. Syncrude had a freshwater consumption intensity of 2.31 m3 /m3 of hydrocarbon production.

In Situ

For our Firebag and MacKay River in situ sites, water is drawn from recycled wastewater from our oil sands upgrading and utilities operations. We also use surface runoff water collected within the facility boundaries and groundwater wells. In 2022, the average water recycling rate at our in situ sites was approximately 98%, reflecting continued operational efficiencies and further site water optimization.

Refining and logistics

Our refineries use fresh water for heating and cooling. All refineries have unique requirements and considerations based on the watersheds in which they operate. The refining and logistics freshwater consumption intensity stayed consistent at 0.23 m3 /m3 refined liquid hydrocarbon production. We continue to explore and implement local initiatives that will result in more efficient water use, with less fresh water drawn from local water sources. None of our assets operate in areas of high risk of water stress. However, Suncor’s Commerce City refinery in Colorado operates in a region that is classified as moderate risk, where water supply shortages would require bringing in water by pipeline or truck. We continue to monitor the status of the basin while focusing on implementing industry-leading innovation at our facilities to reduce, reuse and return water.

Exploration and production

In our East Coast Canada offshore operations, water is either produced offshore through desalination, or is transferred via vessel from St. John’s, N.L. Water data for our Terra Nova Floating, Production and Offloading facility will be reported in 2024.

We believe water is a shared and precious resource. It must be managed wisely using a balanced, integrated and sustainable approach. Read more on how we do that here.