Qualcomm’s 2023 Corporate Responsibility Report: Supply Chain Management

Originally published in Qualcomm's 2023 Corporate Responsibility Report

We work to have a sustainable supply chain management program that emphasizes product quality while minimizing risk and improving overall sustainability. Our due diligence strategy focuses on making appropriate supplier selections, assessing for risk, conducting comprehensive onboarding and monitoring adherence to our Supplier Code of Conduct.

We want our products to be distinguished not only by their capabilities but also by the responsible way in which we design and produce them. Because we primarily employ a fabless production model, we rely on suppliers to perform the manufacturing of our integrated circuit products. We regularly work with the primary semiconductor foundries and assembly suppliers that manufacture our products to assess risks and monitor conformance to our Supplier Code of Conduct.

We expect our suppliers to uphold the same corporate responsibility standards as ours, including respect for human rights, responsible sourcing of minerals, reducing emissions and minimizing use of resources such as water and energy.

As a Full Member of the RBA, we require suppliers to adopt either the RBA Code of Conduct or a similar code. By leveraging RBA tools and resources in our supply chain management program, we can focus on driving our suppliers to conform to high standards in relation to labor issues, health and safety, the environment, ethics and management systems.

The RBA Code of Conduct, which serves as our Supplier Code of Conduct, and The Qualcomm Way: Our Code of Business Conduct, are the cornerstones of our commitment to the RBA and responsible supply chain management.

Understanding risks and enabling supply chain sustainability is a key part of acting responsibly. As part of our risk-based approach, we require our primary semiconductor manufacturing suppliers to complete the RBA Self-Assessment Questionnaire (SAQ) annually. The SAQ is a risk-assessment tool that enables companies to evaluate specific supply chain risk in areas such as labor, health and safety, environment and ethics. The SAQ results from our suppliers have indicated that 100 percent of our primary semiconductor manufacturing suppliers all have low-risk manufacturing facilities according to the SAQ ratings.

Regularly assessing and monitoring suppliers for compliance with the Supplier Code of Conduct allows us to minimize potential harm to individuals, communities and the environment, as well as create more resilient supply chains. In addition to completing the SAQ, our direct suppliers are subject to RBA VAP audits and/ or customer managed audits. We also conduct sustainability audits of selected non-primary manufacturing suppliers and suppliers that are new to our supply chain for conformance to our corporate responsibility requirements.

RBA VAP audits are conducted by our supply chain management team and include RBA Lead Auditor trained personnel who conduct on-site audits of selected suppliers for their adherence to our Supplier Code of Conduct and other corporate responsibility requirements, including product environmental governance and conflict minerals. For more on our audit program, see Human Rights.

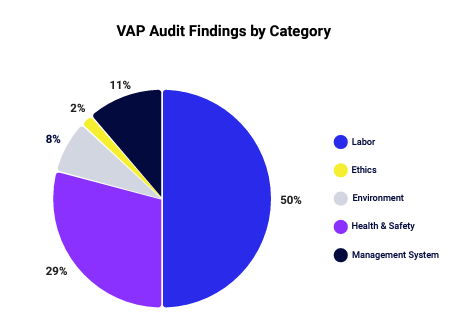

Over the last two years, RBA VAP audits of our direct primary manufacturing suppliers discovered 62 non-compliance findings, of which 19 were minor, 40 were major and three were priority instances of non-compliance. Corrective action plans and closure audits are put in place to resolve non-compliance as part of the RBA VAP audit process.

We have a 2025 goal of ensuring 100 percent of our primary semiconductor manufacturing suppliers are audited at least every two years. As of 2023, 88 percent of them are receiving biennial audits.