Mondelēz 2021 Snacking Made Right Report: Climate Action

Mondelēz 2021 Snacking Made Right Report

From droughts and wildfires to devastating flooding and the chronic impact on our biosphere, wildlife and humankind – the consequences of climate change are everywhere and escalating. Combating climate change is the challenge of our lifetime, and we’re taking action like never before. We’re building on our progress in reducing our end-to-end carbon footprint and working toward our long-term goal of net zero carbon emissions by 2050. In doing so, we’re transforming how we do business across our entire supply chain – from farmer’s field to shop shelf.

"For the last several years, we've worked with the Science Based Targets initiative to reduce our emissions footprint and with our net zero target, we are accelerating our efforts to create a more sustainable snacking company. We're transforming how we do business across our operations and with the suppliers and farmers we work with – from seeking to improve cocoa farming practices in West Africa to promoting regenerative agriculture in wheat fields in the Midwest United States."

Dirk Van de Put, Chairman and CEO, Mondelēz International

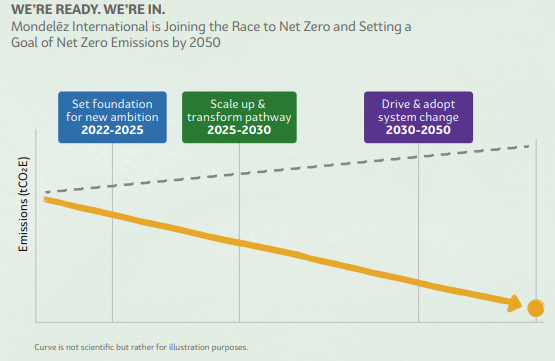

Joining the Race to Net Zero

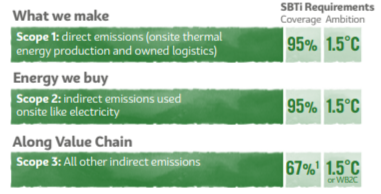

For the past few years we have been on a path to reduce our carbon emissions and in 2021 we took a key step forward – committing to a goal of net zero greenhouse gas emissions across our full value chain by 2050. As part of the goal, we have signed the Science Based Targets initiative’s (SBTi’s) Business Ambition for 1.5°C, aligning our long-term emissions mitigation targets with the aim of limiting temperature rise in accordance with the Paris Agreement. We've also joined the United Nations Race to Zero Campaign to help build momentum towards a decarbonized economy.

Defining Net Zero Carbon

The SBTi Net-Zero Standard defines corporate net-zero carbon as: • Reducing Scope 1, 2, and 3 emissions to zero or to a residual level that is consistent with reaching net-zero emissions at the global or sector level in eligible 1.5°C-aligned pathways • Neutralizing any residual emissions at the net-zero target year and any GHG emissions released into the atmosphere thereafter.

A Clear Way Forward

Achieving net zero is no easy task, but we have set a clear path and know what we have to do to steer toward our long-term goal.

Our principles for transition:

1. We aim to transform the way we do business

2. Build on our existing efforts, scaling proven models for wider impact

3. Collaborate across the industry & sector and engage suppliers

4. Invest in bold innovation to drive technological evolution

5. Be transparent in progress, setting interim targets and communicating regular updates

We’re working with our suppliers and farmers to grow ingredients in ways that protect forests and promote biodiversity.

Across our owned facilities we are converting electricity to renewables, and replacing thermal fuels with low carbon alternatives.

An End-to-end Approach

To deliver lasting change at scale, we are prioritizing where we can have the greatest impact, focusing on innovative and measurable solutions, and collaborating to drive sector-wide transformation.

We're taking an end-to-end approach – from field to shelf – to reach our net zero carbon emissions goal by focusing our efforts across key areas and delivering against set targets.

As we work toward our goal, we’re transforming how we do business – across 150 countries, tens of thousands of suppliers, and hundreds of thousands of farmers. It marks a major step on in our differentiated approach to sustainability focused on driving lasting progress at scale and creating long-term value for our business and stakeholders.

Mondelēz International is joining the race to zero and commits to 2050 net zero emissions goal

Our climate action plan is focused for impact, prioritizing e orts across key areas and delivering against existing goals and targets. We will engage our strategic suppliers, evolve our brand and portfolio, and collaborate with industry partners for greater impact.

Goals – From Field to Shelf

- Cocoa- Source 100% cocoa volume for chocolate brands through Cocoa Life Program by 2025 (cocoalife.org)

- Wheat- Grow 100% wheat volume needed for Europe business unit biscuits production under Harmony charter by 2022

- Dairy- Majority of dairy materials purchased from suppliers operating under animal welfare schemes

- Renewable Energy- Continue to convert global manufacturing electricity footprint to renewable energy

- Oven & Refrigerants- Work toward achieving energy efficiency for biscuit ovens and steam boilers. Start replacing thermal fuels (e.g., natural gas, diesel, gasoline) with ‘green’ alternatives

- Logistics- Investing in new mobility concepts including electric and hydrogen trucks. Reduce warehouse emissions in owned and third-party facilities by converting to renewable energy sources. Improve efficiency of distribution networks

- Packaging- 100% packaging designed to be recylable by 2025. Reduce overall virgin plastic use by 5% and reduce overall virgin rigid plastic by 25% by 2025 (Baseline 2020)

"With our net zero goal, we are accelerating our efforts to create a more sustainable snacking company. We're transforming how we do business across our operations and with the suppliers and farmers we work with – from seeking to improve cocoa farming practices in West Africa to promoting regenerative agriculture in wheat fields in the Midwest United States."

Dirk Van de Put, Chairman and CEO, Mondelēz International

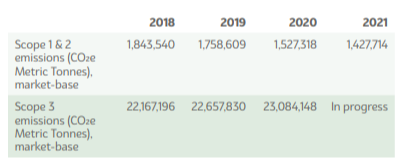

Mondelēz International GHG Emissions

We have been calculating and monitoring Scope 1 and Scope 2 emissions for several years, enabling us to gain experience in setting up carbon reduction programs and related metrices and targets as well as the processes and governance required. As a next step, we calculated and added Scope 3 emissions, to ensure a holistic carbon view across our full supply chain – from field to shelf. Since then we have been busy building out our end-to-end supply chain carbon roadmap, leading to our net zero goal.

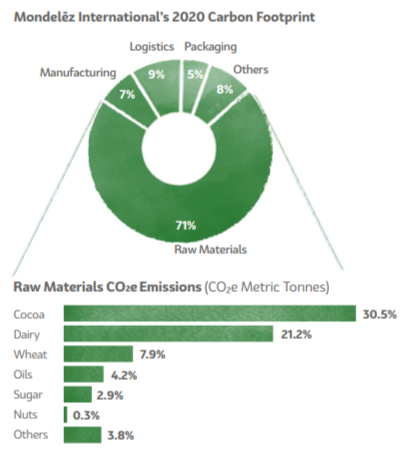

The largest environmental, social and economic impacts related to our business occur outside our direct operations – in fact 94% of our greenhouse gas (GHG) emissions reside in Scope 3 (namely the sourcing of key raw materials). That’s why we take an end-to-end approach to reducing our carbon footprint so we can work to reduce emissions within our owned operations and also, importantly, work to reduce emissions through signature programs designed to achieve more sustainable sourcing of the key raw materials we know have the biggest impact on our overall carbon footprint.

Mondelēz International’s Carbon Footprint

We have been monitoring and implementing programing to decrease emissions across Scopes 1, 2 and 3 for several years, enabling us to gain experience in setting up long-term and more ambitious carbon reduction programs and related metrices and goals as well as the processes and governance required.

We have also been calculating our Scope 3 emissions for several years and, as a next step as part of joining the SBTi Race to Net Zero are currently working with our external carbon experts and partners on a planned model revision allowing us to incorporate our Scope 3 interventions into the carbon model, review the materiality of recent acquisitions as well as incorporate planned updates to carbon accounting standards and recommendations set by the SBTi and the GHG Protocol, both targeting to enhance clarity around Scope 3 definitions.

~70% of Mondelēz International’s CO2e emissions comes from our raw materials, concentrated in four key commodities so more sustainable sourcing of these key raw materials will have biggest impact in reducing our overall carbon footprint.

We have been implementing programs to reduce Scope 3 emissions that we are currently in the process of translating into carbon emissions reductions. We are focused on scaling signature sourcing programs in Cocoa and Wheat where thirdparty verified impact data gives us confidence to confirm our programs have a direct impact on emission reductions. For more information on the impact of our signature sourcing programs on a forest positive future please see page 53 .

We’re working with our suppliers and farmers to grow ingredients in ways that protect forests and promote biodiversity globally with tens of thousands of suppliers, and hundreds of thousands of farmers.

Assessing Our Carbon Footprint

We take a thorough approach following the internationally recognized GHG Protocol Standards to calculate, annually, our total carbon footprint across our end-to-end supply chain, covering Scopes 1, 2 and 3.

We assess the following activities:

Scope 1 emissions:

- Combustion of fuels in our owned and operated facilities

- Combustion of fuels in our owned and operated mobile sources

- Fugitive emissions from our owned and operated manufacturing sites

Scope 2 emissions:

- Indirect emissions associated with purchased electricity, heat and steam in Mondelēz-owned and operated facilities

Scope 3 emissions :

- Purchased goods and services (including effects of Direct Land Use Change)

- Fuel and energy related activities

- Upstream transportation and distribution

- Waste generated in operations

- Business travel

- Employee commuting

- Downstream transportation and distribution

- Use of sold products

- End of life treatment of sold products

Focusing End-to-End

We look at each individual step within our supply chain to understand the contributors to our carbon footprint and where our focus matters most.

2025 Goal

-10%

Our goal is to achieve 10% end-to-end CO2e emissions reductions by 2025 (vs 2018).

Our Ambition

We are in the process of adjusting our path towards net zero, which is subject to verification by the SBTi (by 2023 latest). In the meantime, we continue to deliver against our 2025 public goals, including reducing our absolute end-to-end greenhouse gas emissions by 10% by 2025 vs a 2018 baseline, which is equivalent to a 23% reduction vs business-as-usual.

Following the SBTi guidelines, we focus our carbon reduction programs on the categories of GHG emissions that are most impactful for Mondelēz International. This represented 20.3 million metric tonnes CO₂e in 2020 (or 83% of our total value chain GHG emissions footprint). Accordingly, we include the following GHG emissions in our goal setting: Scope 1, Scope 2 and major elements of Scope 3: purchased goods and services and waste generated in operations.

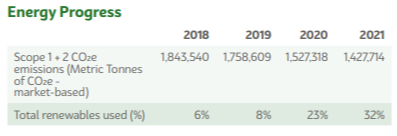

In 2021, we reduced our Scope 1 and 2 (market-based) emissions by 21% versus our 2018 baseline by continuing to improve energy efficiency and increase our use of renewable energy.

We have been implementing programs to reduce Scope 3 emissions that we are currently in the process of translating into carbon emissions reductions.

Energy Progress

Electricity and natural gas energy sources are the largest contributor to our manufacturing footprint and so are a major focus of our carbon reduction efforts.

We continuously invest in energy management systems and energy efficient technologies in our factories. We are also using low-carbon renewable energy sources to reduce our CO2e emissions.

Improving Energy Efficiency

In 2021, several energy efficiency projects were implemented across our manufacturing network. Here are some examples:

- In South Africa, our Port Elizabeth site installed four centralized chiller units, saving 380 MWh per year in refrigeration, reducing CO2e by 2240 metric tonnes.

- Meanwhile in Poland, our Skarbimierz plant optimized its refrigeration system with the installation of dry coolers as a free cooling loop, reducing the workhours of the chillers and in so doing cutting out 1,300 metric tonnes of CO2e.

- Our East Suzhou plant, in China, is using the 200°C air emitted by its ovens to heat water and generate savings across the refrigeration process and other systems – saving 334 metric tonnes of CO2e.