Mondelēz 2023 Snacking Made Right Report: Aiming To Advance a More Circular Economy for Packaging

We work hard to use packaging that does more than protect our products and delight our consumers. At Mondelēz International, we strive to continually improve our packaging with the long-term aim of advancing our support for a more circular economy for packaging.

We believe that by continuously improving our packaging and measuring our performance, we can work towards our long-term aim of advancing our support for a more circular economy for packaging. For us, this is based around a three-part approach that helps us utilize packaging that is both light and right. The three parts are:

Reducing Packaging by aiming to utilize packaging that is light, safe and, when appropriate, can be reused or recycled.

Evolving Packaging involves evolving our packaging so that it’s designed to be recyclable, and utilizes recycled plastic content, where appropriate, to help drive down packaging waste. Our key goal is to use packaging that is designed to be recyclable and continue our use of recycled content.

Improving Systems means supporting the development of infrastructure and capabilities with a goal of being able to collect as much plastic as we put into the environment. As part of this, we are supporters of policy development and Extended Producer Responsibility (EPR) schemes to cover the development of systems supporting collection of all types of plastic packaging, and are involved in ongoing collaboration with governments, peers and others.

Significant progress has been made across the global business to integrate our Global Sustainable Packaging Strategy into our local business strategies and roadmaps. Over the past 18 months we have worked with our local market teams through bespoke workshops, capability building and training to develop comprehensive, locally-relevant programs for more sustainable packaging that recognize the local market environment.

We also recognize that cross-functional collaboration is critical to our success and to our ability to deliver more sustainable solutions for packaging, now and in the future, especially in the areas of:

- New innovative materials that support increased circularity and provide sufficient quality and safety for our products.

- Sourcing of new technologies such as materials made from recycled plastic waste.

- Globally consistent support for policy development and advancement of infrastructure.

As we continue to build on our strong foundations, we move closer to meeting our goals and advancing our support for a circular economy for packaging.

REDUCING PACKAGING

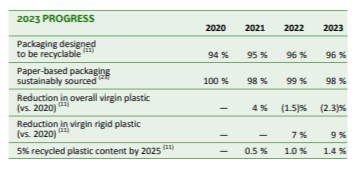

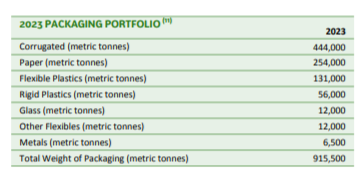

We remain on track to achieve our 2025 goal of 5% reduction vs 2020 levels in our use of virgin plastic and are set to see progress in the year ahead in line with expectations. Thanks to the slowly increasing availability of new materials, such as recycled content for flexible film in key markets, as well as supply chain adjustments and successful line trials across a complex network of manufacturing facilities we continue to make progress. In 2023 we were able to reduce our plastic packaging footprint by about (2.3)% versus 2020 (11), offsetting the significant growth that our business has been able to deliver. In our rigid plastic portfolio we have been working with suppliers to secure new innovative materials and planning trials that will enable us to drive scale as we expand these initiatives across markets while continuing to maintain our high standards for safety and quality.

Mondelēz International is one of the founding business signatories to the Ellen MacArthur Foundation (EMF)’s Global Commitment, which unites organizations behind a common vision of a circular economy for plastics. Of the 123 businesses that contributed data for the EMF’s 2023 Global Commitment Progress Report, we were delighted to be singled out as the brand that reported the highest tonnage elimination of plastic packaging: over 12,000 metric tonnes. This was achieved by moving about 71% of our polystyrene (a versatile material that can be rigid or formed) to polyethylene, terepeththalate (a clear, durable and versatile material), eliminating all undetectable black plastic from our portfolio with a specific focus in North America and resizing products resulting in reductions in metric tonnes of plastic packaging used.

“With the launch of the Ellen MacArthur Foundation’s Global Commitment, leaders within the plastic packaging industry joined forces to drive action and achieve systems change. Five years later, it is clear that voluntary action can make meaningful progress, but more has to be done to end plastics waste and pollution. Despite outperforming the rest of the market, signatories are expected to miss some of their 2025 targets. We therefore welcome Mondelēz International’s efforts to eliminate problematic or unnecessary plastic packaging. In our 2023 Progress Report, Mondelēz International was the brand reporting the highest elimination of plastic packaging, or 12,825 metric tonnes. We need more brands to follow their lead.”

Aisha Stenning

Programme Manager for Plastics

Ellen MacArthur

EVOLVING PACKAGING

We continue to make meaningful strides in the evolution of our packaging material. As of the end 2023 approximately 96% of our packaging was designed to be recyclable (11) with many markets now close to achieving our ambition and we continued to achieve this performance while experiencing strong growth of non converted materials across our portfolio.

We continue working across our markets to recognize local requirements, educating suppliers on Mondelēz International and industry standards, and collaborating with our peers amongst other actions. To account for various strategic and operational factors including but not limited to our mergers and acquisitions strategy and growth, as well as external factors like evolving regulatory requirements, we are updating our goal to: We aim to have approximately 98% or more of our packaging designed to be recyclable by 2025 .

We continue to collaborate within the industry and across sectors to ensure that the actions we take can have the scaled impact we need to see. In 2023, we became members of the Ocean Plastics Leadership Network (OPLN), a global multi-stakeholder community dedicated to ending plastic pollution in our oceans. With OPLN we are working with our peers along the value chain to produce responsible production guidelines for advanced recycling.

Further, with the CGF we continue to support advancement of the Golden Design Rules, and as co-chairs of the CGF Plastic Waste Coalition of Action’s Flexibles Working Group we work with our peers to help advance circularity for flexibles, such as EPR for flexibles.

In the U.K. for Christmas 2023, we evolved our core Cadbury selection boxes to include trays made with about 80% rPET – post-consumer recycled plastic PET. This material is widely collected as part of household recycling and consumers can check online whether it is collected near them. This move enabled us to remove several hundred metric tonnes of virgin plastic contributing to our 2025 sustainable packaging goals and as actionable progress toward our U.K. Plastic Pact goals.

In Norway in 2023, we also announced the launch of Kvikk Lunsj made with recycled plastic packaging. The outer packaging of the chocolate sold in 3-, 4- and 6-packs now consists of majority ISCC mass balance certified recycled plastic.

Bureau Veritas UK Limited (Bureau Veritas) was engaged by Mondelēz International to provide limited assurance of its 2023 performance on their plastics and packaging material consumption and targets included in the above chart. This assurance statement can be found in our ESG Reporting & Disclosure Reporting Archive.

“Our strategy is based on reducing the amount of packaging we use, simplifying materials so they can be recycled and using recycled materials where we can. But progress demands much more. I’m proud of the leadership role we’re playing as we continue to call for and invest in innovation and partnerships that can create lasting solutions and of the significant collaboration realized across MDLZ teams to integrate our global strategy into local business roadmaps. Building these capabilities across our business helps us to go further, faster with comprehensive, locally relevant programs for more sustainable packaging.”

Emma Beard

Vice President, Global Sustainable Packaging,

Mondelēz International

IMPROVING SYSTEMS

Systems and infrastructure are critical for packaging materials to be recycled in practice. As such, along with local market engagement in policy design and informal and formal development, we continue to play an active role in the UN Global Treaty for Plastic Pollution via the Business Coalition. We are active members of its policy working group, which aims to harmonize regulation on reduction, circulation and prevention. The group is also part of the EMF and World Wildlife Fund’s (WWF) joint working group on policy development. In 2024 – a decisive year – the group aims to align on a treaty seeking to end plastic pollution by 2040.

In the Philippines, meanwhile, we partnered with PCX with a goal for the recovery and diversion of all of the equivalent of our in-market yearly plastic packaging output. PCX partners with organizations that collect and divert post-consumer waste in a credible, traceable, transparent and socially-responsible manner.

In 2023 we expanded our investment in Circulate Capital beyond Southeast Asia and India to the newly established Latin America Fund. The fund aims to enhance focus on the physical collection of flexible films – lightweight, multi-layer plastics used by the snacking industry – that have traditionally been more difficult to collect, sort, recycle and ultimately reuse.

Since the Circulate Capital fund was launched in December 2019 and by December 2022 they have invested more than $80MM in 14 companies, prevented approximately 130,000 tons of plastic leakage and reduced or avoided approximately 200,000 tons of Co2e emissions from plastic recycling. The expansion of the fund to new geographies presents even greater opportunities to have a scale impact and help support circularity for packaging.

CIRCULARITY IN PRACTICE

Working towards a circular economy will demand infrastructural development, widespread investment, an enabling policy and regulatory environment, and cooperation between multiple stakeholders over the long term.

There are many challenges, due to the need to develop roadmaps across many countries, shift complex supply chains and source highly sought-after and costly materials.

Collaboration is key, and we are committed to working closely with our peers and other stakeholders, particularly on innovation to replace challenging materials with more sustainable alternatives. Progress via collaboration isn’t always as rapid as we’d like, but our steady advancement together is helping drive positive change across many markets.

As part of our commitment to working in collaboration with others across the sector, in 2023 we became a Founding Member of the Circular Action Alliance (U.S.). In this Alliance, alongside 18 other Founding Members, we work together as producers to help improve systems consistent with meeting EPR obligations as a step forward in seeking a more circular pack economy.

In 2023 we joined forces with leaders in the packaging supply chain to further advance a more circular economy for plastic packaging in Australia. Together with Amcor, a global leader in developing and producing responsible packaging solutions, Mondelēz International is investing in advanced recycling technology pioneer Licella. Our investments aim to help Licella progress construction of one of the first advanced recycling facilities in Australia. Licella aims to use its innovative Catalytic Hydrothermal Reactor (Cat-HTR™) technology to recycle end-of-life plastic back into a crude oil substitute suitable for producing new food-grade plastic packaging. Mondelēz International has already launched Cadbury Dairy Milk packaged with 30% recycled content in Australia and this partnership is anticipated to enable further portfolio expansion in the use of recycled content.

“Investing in the latest technology helps accelerate our transition to a more circular pack economy. Cadbury in Australia is fueling a focus on soft plastic increased circularity, now using more recycled content.”

Darren O’Brien

President, Australia, New Zealand & Japan,

Mondelēz International

View the full 2023 Snacking Made Right Report

(11) Reported information covers the period from November 1, 2022 through October 31, 2023.