What’s the Buzz About Ultrasonic Testing?

This story first appeared on Baker Hughes’ Energy Forward Stories.

What do bees and ultrasound equipment have in common? The answer is Michael Geng, beekeeper and engineer at Baker Hughes in Hürth, Germany.

But there is another link: both ultrasound and bees use vibrations to do their important work. The non-destructive ultrasound testing and portable instruments produced by Waygate Technologies, a Baker Hughes business, use high-frequency sound waves to inspect infrastructure, components and materials for internal flaws.

Michael explains, “Our equipment transmits ultrasound at frequencies of a couple of megahertz, and it gets reflected if there's a flaw in the material.” This is particularly relevant to maintaining pipelines, or EV batteries for example. He explains, “We can inspect connections such as welds, or measure thickness and potential points of weakness or wear in pipes; detect cracks and voids in train tracks or aircraft wings.”

Also applied to assurance testing in automotive, electronics and additive manufacturing industries, portable non-destructive testing (NDT) is invaluable for analyzing the quality and therefore safety of materials, in situ, and without having to break it apart.

Bees, on the other hand, communicate in part via vibroacoustic signals – which can be generated by behaviors such as body or wing movements, or pressing their thoraxes against hive substrates. Science has shown that there is a “strict correlation” between the frequencies of vibroacoustic signals and the amplitudes detected inside the honeybee hives and the imminence of events such as swarming.

Kindergarten — a hive of inspiration

Michael was inspired to keep bees when he met another father at the kindergarten attended by his then toddler daughters, Paula and Lena. “He was a beekeeper, and back in 2017 he directed me to a training course. I thought this could be interesting, so I signed up. Even during training, I became so keen I bought two beehives, and since then my hobby has grown every year,” says Michael. He now keeps hives in his own garden and in the garden of a friend who lives in a nearby street.

Importantly, he is now able to keep his colleagues and local neighborhood supplied with honey. “Once a year, I put on a special honey event in our lab at work, and I invite employees from our facility to try and buy honey if they like it – some kind of ‘Honey Happy Hour’ so-to-speak. During the year I also keep a few jars of honey at my desk, so whenever anybody at work needs to replenish their pantry, they can easily come and get some.”

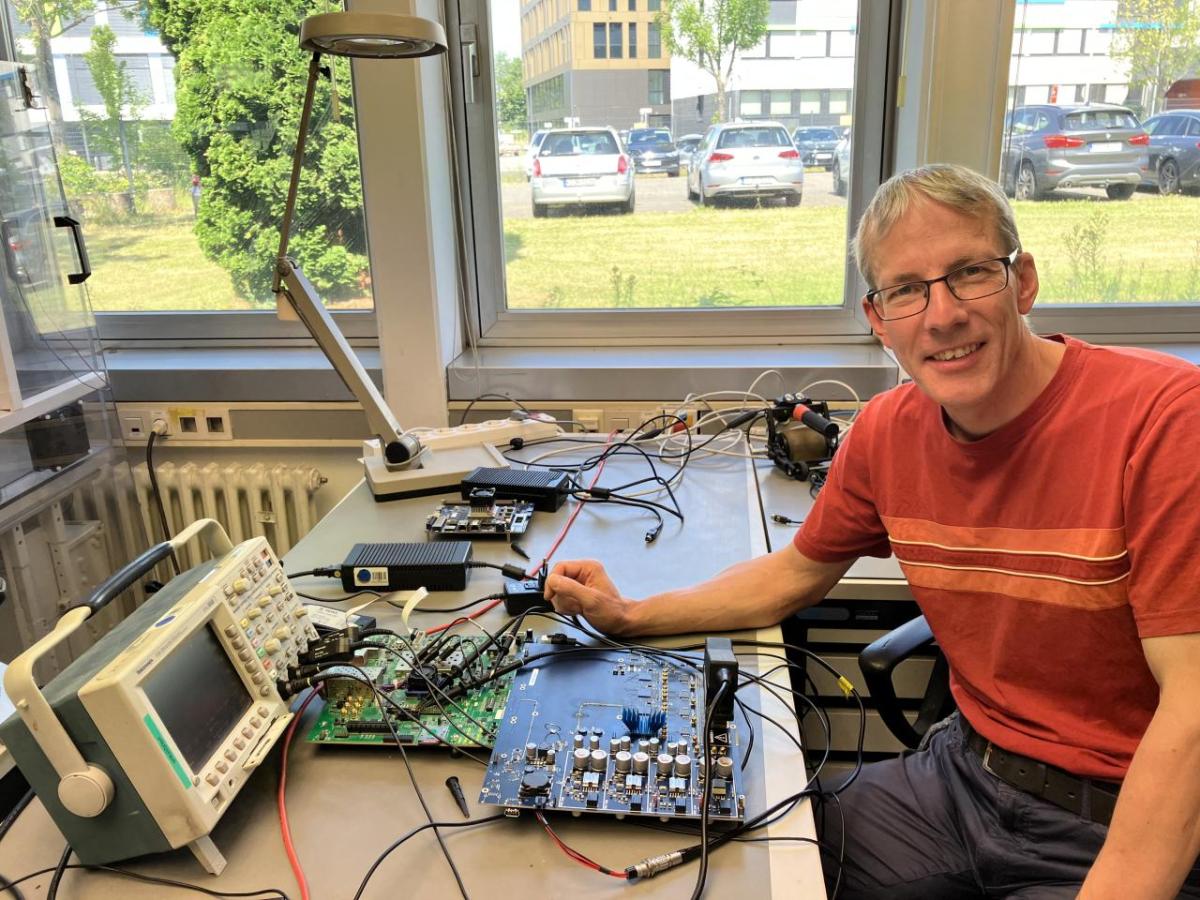

Honey sales aside, Michael’s main pursuit at the Baker Hughes’ facility in Hürth is developing combined “software, firmware and electronic schematics, or printed circuit boards” to further advance Waygate’s NDT capabilities. The company focuses on the digital transformation of industrial inspection and provides data-driven insights that redefine quality assurance.

“Our intelligent inspection data and cutting-edge digital platforms make the most of our worldwide network to drive smarter industrial decisions and enable targeted predictive maintenance,” he says. “They help to further reduce downtime in industry, improve compliance and traceability and ultimately enhance overall operational efficiency.”

A man for all seasons

In his 24-year career with the company, Michael has led and contributed to the development of numerous products, including the Krautkrämer USM100 portable flaw detector, which has smartphone-like capabilities. Designed to allow operators to perform comprehensive and accurate inspections in the field, it is used in a wide variety of applications including weld and corrosion inspection, inspection of composites such as carbon fiber used in wind turbine blades, and in nuclear plant inspection.

Honey production is somewhat less digitally managed, although Michael does have a website outlining his products and services. He divides his homemade products broadly into spring and summer harvests and their distinctive flavors.

With a rich history, and the remains of a Roman aqueduct passing through it, Hürth is now considered an outer “suburb” of the city of Cologne and has long been known for its support of heavy industries such as mining, energy, manufacturing and machinery production. Baker Hughes itself has more than 125-year history in the area, as the trusted partner of industries that rely on precision, safety and productivity.

Even so, says Michael, the suburban gardens of Hürth are verdant in the warmer months with a wide variety of flowering plants and fruit trees. Although he can not track his bees’ movements, Michael says his spring honey, which he produces in both runny and creamed varieties, owes its caramel-like flavor to cherry and apple blossoms, spring flowers and rapeseed plants.

In summer, as the temperatures in northern Europe ramp up, Michael’s bees seek out the blossoms of surrounding Linden trees, also known as Lime trees (although they have nothing to do with citrus), to produce a fresher, lighter honey.

Paula and Lena, now in their teens, like to help their father with his sweet side hustle, mostly to do jobs such as distributing flyers around the neighborhood, advertising the available sorts of honey. Michael processes and packages the harvest at home, using a centrifuge to separate the solids such as wax from the liquid gold, and further straining the honey into jars. His labels, “Efferener Bienenhonig” refer to Efferen, the district of Hürth that he and his bees call home.

He sells his honey and his latest product, mead, from his doorstep. He also sells bee colonies to other would-be beekeepers and is on call to come and collect unwanted swarms.

Sustainability in all its forms

Michael says his hobby enhances his wellbeing and pleasure in life. “At work, I sit at a desk in front of a computer, using my head. Looking after the bees, I'm in nature, at least in my garden, working with my hands.” He concedes that he would also enjoy spending his spare time programming, “but then I would sit in front of a computer all the time”. Beekeeping and electrical engineering, he says, are perfectly complementary.

A deeper contribution to sustainability is another factor common to non-destructive testing of materials and beekeeping.

Says Michael, “Pipelines transporting oil and gas must be regularly inspected, to prevent leaks that can impact the environment and cause costly losses to producers.” In refineries, testing and maintenance of equipment is critical. “Energy must be produced from hydrocarbons efficiently and avoid waste,” he says. Michael also cites the steel mills which use NDT to ensure the quality of their products from the outset.

Meanwhile, climate change, destruction of habitat and overuse of agricultural pesticides are some of the causes of the decline in global wild bee populations. Germany has recorded some 550 species of bees, and there are almost 2,000 known species in Europe. The European Environment Agency cites “strong evidence of a dramatic loss of wild pollinators, including wild bees, hoverflies, butterflies and moths”. This puts agriculture and food security at risk since around 84% of European crop species depend at least in part on wild pollinators for fertilization, seed production, and quality and yield of crops.

“We have one species of honeybee, and it is not at risk,” says Michael “because honeybees are managed and beekeepers take care of them.” As such honeybees can provide an important contribution to pollination, both in gardens and on a larger, agricultural scale, while governments develop policies that help ensure the continued diversity of bees and other pollinating insect species.

A Sound Future

As industries face increasing pressure to reduce downtime, improve safety, and meet environmental standards, the role of advanced NDT solutions becomes ever more vital. Michael’s work helps ensure that Baker Hughes remains at the forefront of this transformation—delivering intelligent inspection tools that support predictive maintenance and smarter decision-making.

In both his professional and personal life, Michael is driven by care, and a commitment to quality. Whether he is analyzing ultrasonic waveforms or harvesting honey, he is helping build a more resilient and sustainable future—one vibration at a time.