Towards a Brighter Future

by Alexandre Lalumiere, Director of Client Sales, 3D Printing, HP

Originally published on LinkedIn

Yesterday, I participated in Shell’s #MaketheFuture Festival Singapore, and was among the panelists during the Shell #PoweringProgress Together (PPT) Asia forum. The energy was positively electric!

I got to meet students from Thailand’s Chiang Mai University who presented their visions on the future scenarios of cleaner energy use in Asia and Middle East cities. I also heard from #IdeaRefinery start-ups doing amazing things like building energy efficient homes for the homeless and delivering wireless charging for battery-powered cars. I even got to drive one of the cool energy-efficient cars at the event!

I had the pleasure of discussing HP’s leading sustainability innovation and initiatives with public and private sector leaders at the Shell PPT Asia Forum. It brought together over 150 leaders, young talents and representatives from the public and private sectors. We discussed and debated how to deliver “Energy for Better Living” and tackle future energy challenges.

Over the last four years, HP provided IT infrastructure for Shell’s Make the Future event as its Festival Partner. Using our solutions that deliver lower energy consumption and efficiency, we showcased the use of energy efficient technology while driving sustainability discussions through the PPT Forum.

Shell and HP, together with other partners, also developed the Global Logistics Emissions Council (GLEC) framework, which helps companies understand its carbon footprint, cost and time used across multiple modes of transportation. This framework enables companies to outline efficient goods transportation methods while significantly minimizing harmful emissions from their supply chains.

Every second, a printer and 1.7 PCs are shipped from HP to customers all over the world. This calls for one of the most dynamic and extensive supply chains in the IT industry to ensure we meet the constantly evolving needs of our customers. However, this also accounts for about 45 per cent of HP’s carbon footprint. That’s why HP has taken significant steps to transform our supply chains, innovate responsibly and reduce environmental impact.

Here’s how we are doing our part:

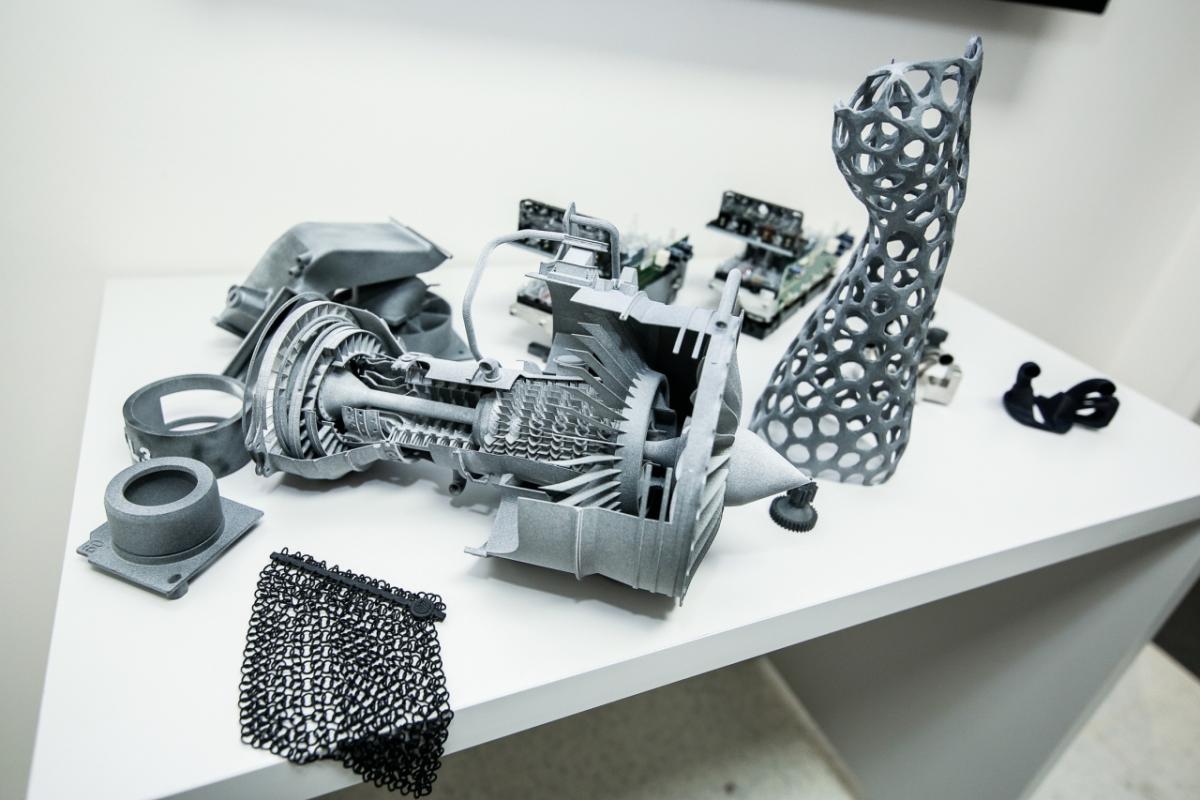

A) Digital transformation of the traditional supply chain with 3D printing

HP’s 3D Printing technology can help our customers shorten their supply chain, reduce their carbon emissions, eliminate production waste, while being more cost-effective. 3D printing enables “just in time” delivery and brings the production closer to the consumer, all while reducing the environmental impact associated with the transportation of parts from large regional or global warehouses. By producing parts on demand, we also reduce the amount of materials that must be stored physically. Bringing revolutionary solutions that were never possible before, HP is set to disrupt the $12T manufacturing industry.

B) Propelling a circular, low-carbon economy

We are moving from a linear manufacturing process towards a more circular, “make-use-return” approach across our entire supply chain. A key example would be a project in Haiti, where we created a new demand for used colored plastic bottles by using them to manufacture new ink cartridges. In doing so, we are recycling resources to create sustainable ink cartridges and reducing ocean pollution while creating jobs for the collectors of recyclables in Haiti.

C) Service-based business models

HP’s expanding service-based business offerings help our customers get access to our latest technology, while reducing capital costs and accelerating their transition to a circular economy. HP Device as a Service (DaaS) provides a complete solution that combines a full portfolio of products with life cycle management services. Likewise, HP’s Managed Print Services (MPS) helps customers optimize, manage and improve their printer fleets and digital workflows. Printers and PCs deemed no longer functional are recycled in a responsible manner in accordance with HP policies.HP is also exploring ways to improve productivity across its own global supply chains. HP’s Smart Manufacturing Application & Research Center (SMARC) in Singapore is helping to digitally transform and reinvent HP’s Supplies manufacturing processes globally by leveraging next-generation technologies like 3D printing, robotics and data analytics.

Apart from systematically analyzing our carbon footprint and taking measures to reduce our Greenhouse Gas (GHG) emissions across our entire value chain, we are helping more than 200 suppliers across Asia reduce energy use, GHG emissions and costs through our Energy Efficiency Program – a collaboration with several partners.

HP’s vision is to create technology that makes life better for everyone, everywhere. If we all did our part to ensure that we progress and innovate sustainability, the world will become a better place for future generations to come.