Tetra Pak Sustainability Report FY22: Taking Action on Climate

According to the latest Intergovernmental Panel on Climate Change (IPCC) Report, the world is already 1.1°C hotter than preindustrial levels, and unfortunately, the global climate crisis continues to grow increasingly dire3. Keeping warming to 1.5°C above pre-industrial levels requires deep, rapid and sustained greenhouse gas (GHG) emissions reductions in all sectors. The National Oceanic and Atmospheric Administration (NOAA) and NASA reported 2022 to be one of the hottest years with some of the most extreme – and most costly – weather events on record4.

Corporate sustainability leaders have taken action. Currently, more than 40% of the world’s largest publicly traded companies have made net-zero commitments as of the end of 2022, up from 20% in December 20205. However, only 50% of companies with net-zero targets were found to have a GHG emissions reduction plan that includes intermediate targets6.

Food systems are sustained by carbonintensive activities including agriculture, land use, and supply chain activities such as industrial processes and packaging, and account for one-third of total GHG emissions7. As of April 2023, more than 4,500 companies have set or committed to developing science-based targets8, 290 of which are from the food and beverage processing sector and only 87 are from the containers and packaging sector9.

Why it matters

The world is already 1.1oC hotter than pre-industrial levels. To avoid the widespread adverse impacts and related losses and damages to nature and people, keeping warming to 1.5°C above pre-industrial levels requires deep, rapid and sustained GHG emissions reductions in all sectors.

Ambition

Take action on mitigating climate change by decarbonising10 our operations, products, and our value chain.

Targets

- By 2030, achieve net-zero GHG emissions in our operations (scopes 1 and 2 and business travel)11 and -46% GHG reduction across our value chain in line with 1.5°C SBTi commitment compared to our 2019 baseline12

- By 2030, source 100% renewable electricity in our operations in line with RE100 commitment

- By 2030, reduce the carbon footprint of our best practice processing lines by 50% compared to 2019

- By 2050, work together with our suppliers, customers and other stakeholders to achieve net-zero GHG emissions across our value chain (scopes 1, 2 and 3)13 compared to our 2019 baseline

Tetra Pak’s role

As a leading manufacturer of food packaging and processing solutions our value chain relies on natural resources such as water, forests, and minerals, all of which are increasingly at risk as climate change amplifies droughts, deforestation, and depletion of mineral resources. We are looking at the whole value chain, from working upstream on (1) raw materials and transportation, decreasing GHG emissions in (2) Tetra Pak’s operations, to working with customers downstream on the impact of (3) sold equipment.

At Tetra Pak, we commit to addressing climate change and recognise the importance of setting ambitious targets for transparent and meaningful climate actions, that are aligned with best practices. A critical part of our climate strategy is to work together with our suppliers, customers and other stakeholders to achieve net-zero GHG emissions across the value chain (scopes 1, 2, and 3)14 by 2050 from a 2019 baseline, a target which has been approved by the Science Based Target Initiative (SBTi)15. To achieve this, we have set a goal to achieve net-zero emissions in our operations (scopes 1, 2 and business travel) by 2030. Our net-zero trajectory comprises reduction, mitigation, and compensation measures across our operations as well as relevant parts of the value chain, from raw materials to impact of sold equipment and packaging. These efforts not only help mitigate our own climate impact but also contribute to keep global temperature rise limited to 1.5°C globally16.

READ MORE

Our progress in 2022

Raw materials

We aim to reduce the climate impact of our suppliers’ materials by working collaboratively replacing fossil-based plastics with plant-based plastics and testing a fibre-based barrier to substitute the aluminium foil layer in aseptic carton packages.

Collaborating with our suppliers to reduce climate impact

Since launching our ‘Join us in Protecting the Planet’ initiative two years ago, we’ve been working closely with 45 out of 60 of our base materials suppliers17 to improve on the areas of climate, biodiversity, and circularity. These 45 suppliers account for 99.5% of our purchase volume and 99% of our base materials' GHG emissions in 2022. We have set 20 actions across Climate, Biodiversity, and Circularity, committed to by our base materials suppliers between now and 2030 – ‘Twenty actions by 2030’. Our aim is for our suppliers to reduce their GHG emissions by 50% by 2030 by setting actions to decrease the climate impact of purchased raw materials.

Replacing fossil-based with plant-based plastic

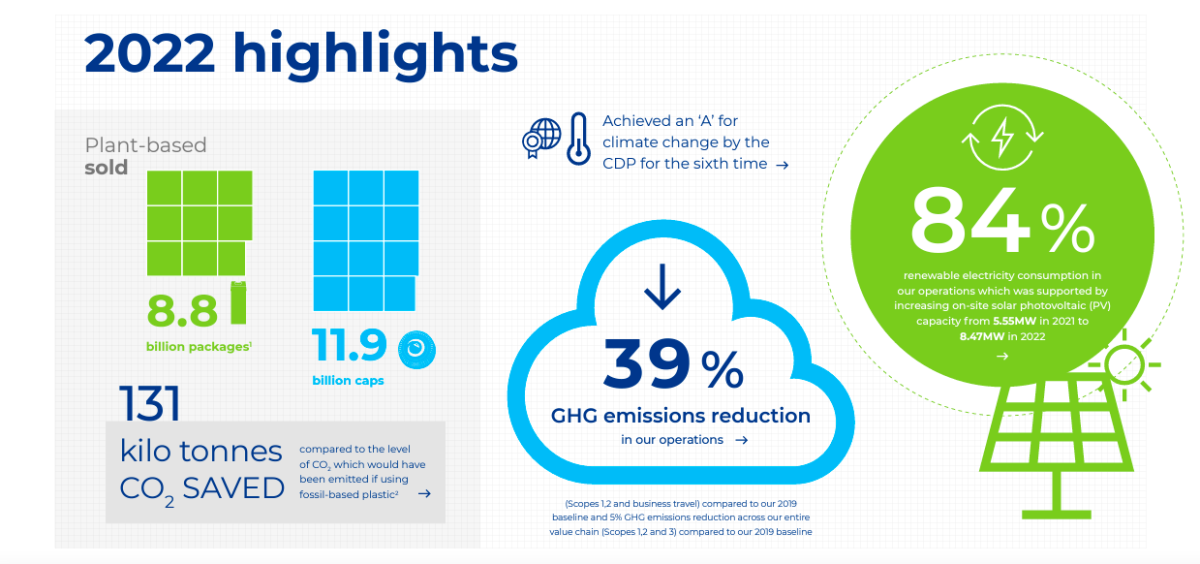

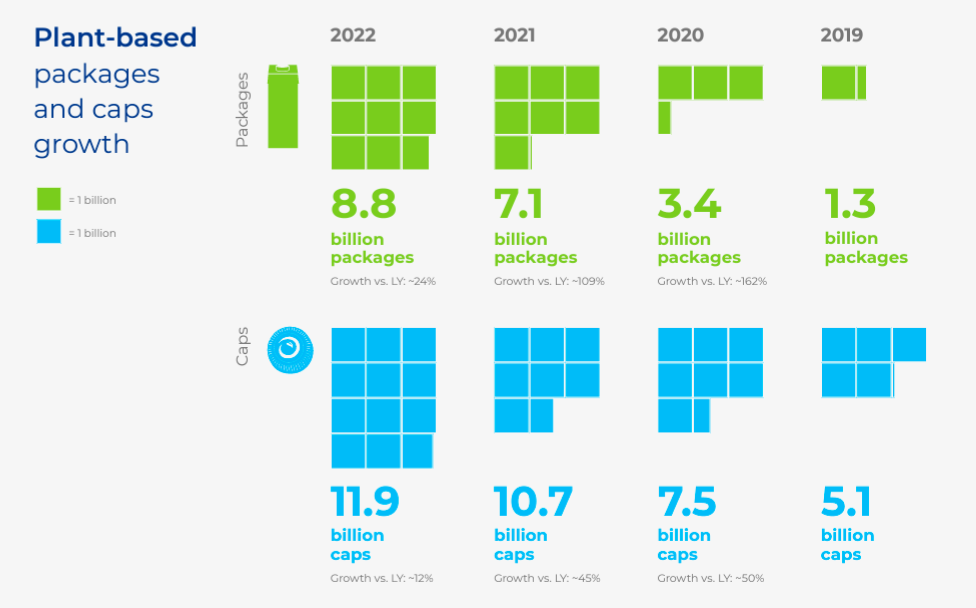

We have increased the use of plant-based plastics over fossil-based plastics, selling 8.8 billion plant-based packages18 and 11.9 billion plant-based caps in 2022, compared to 7.1 billion and 10.7 billion respectively in 2021. The amount of plant-based plastic, which amounts to approximately 9% of the total amount of plastic we bought in 2022, resulted in 131 kilotonnes of CO2 saved compared to the amount of CO2 which would have been emitted if using fossilbased plastic19.

Replacing aluminium foil with a fibre-based layer

Marking a breakthrough in our journey towards a fully renewable aseptic carton package, in 2002 we tested a fibre-based barrier to substitute the aluminium foil layer in aseptic carton packages, a first within food carton packages distributed under ambient conditions. Early results suggest that the package with a fibre-based barrier can offer CO2 reduction when compared to traditional aseptic cartons20, with comparable shelf life and food protection properties21. Cartons with higher paper content22 are also more attractive for paper mills; thus, this concept presents clear potential for realising a low carbon circular economy for packaging23.

Tetra Pak’s operations

In 2022, we have reduced our operational footprint (scopes 1, 2 and business travel) by 39% compared to our 2019 baseline. This reduction was mainly driven by reduced business travel compared to the 2019 baseline and a strongly increased use of renewable electricity and also supported by reductions in our scope 1 emissions as we focus on shifting away from fossil fuel use.

READ MORE

We have been recognised for leadership in corporate transparency and performance on climate change by the global environmental non-profit CDP. We have been reporting on climate change since 2009 having secured a place on its prestigious ‘A List’ a total of 6 times for climate. In 2022, Tetra Pak was one of the 296 companies that achieved a ‘A’ in climate change, out of nearly 15,000 companies that were scored.

All businesses must have clear targets and plans to align their value chain impacts with what our planet can sustainably provide. Tetra Pak is one of just 18 companies in the world to have a place on CDP’s A List for climate change and forests in 2022. This small group of companies are leading the pack when it comes to transparently disclosing and acting on their environmental impacts.

Maxfield Weiss,

Executive Director CDP Europe

Targeting 100% renewable electricity use in our operations by 2030

In line with the RE100 commitment we made in 2016, we have achieved 84% renewable electricity consumption in 2022 as a result of increasing our on-site solar photovoltaics (PVs) capacity from 5.55MW in 2021 to 8.47MW in 2022. This increase includes the new installation of 6,500 m2 of solar PVs on the rooftops of our Kunshan Integrated Site in China generating up to 1200 MWh annually, avoiding 850 tons of CO2 emissions per year alone. This is one of the concrete measures that Tetra Pak China has taken to achieve carbon neutrality across all its operations by 2030 and across its value chain by 2050.

We are convinced that collaboration across the value chain can help to establish the concept of sustainable consumption more effectively where we reduce CO2 emissions, necessary for the creation of a low-carbon and circular economy in China24. Our carbon neutrality targets and action plan is both a goal and a solemn commitment.

Paul Zhu,

President of Tetra Pak Greater China

In 2022, our factory in Chakan, India, shifted from onsite natural gas energy generation to grid electricity. Once the switch was completed in Q4 2022, the site saw a reduction in direct emissions by 3.1 kTCO2 e. We expect a further 10.3 kTCO2 e reduction for the full year 2023. In total this will lead to a 20% reduction in direct emissions and an 8% reduction (100,000 m3) in water consumption previously used to cool the gas generators25.

Increasing energy efficiency with the Common Energy Monitoring Platform (CEMP)

One of the important measures we have taken to reduce energy consumption while increasing efficiency is the CEMP project, which focused on creating a common platform that enables transparency of overall energy usage, cost, and production, as well as indoor/outdoor climate and weather data in real-time across all our sites. A baseload test conducted in November 2022 at our Rubiera plant in Italy highlighted the potential to reduce out-of-hours consumption by 65%. This translates to a 6% reduction in overall site consumption. Following the successful pilot, the goal is to implement the initiative across all sites by 2024.

Increasing energy efficiency in our offices

We also aim for energy efficiency in our offices, with our new Pacific Center Tower offices in Panama having achieved LEED Platinum26 and Fitwel 3 Stars certification27. Both ratings focus on buildings that improved efficiency, lowered their CO2 emissions, and optimised health and wellbeing for people.

Phasing out the use of fossil fuels in our onsite vehicles

We are switching to electric factory forklifts used in production and warehousing. Tetra Pak Queretaro, Mexico, is moving the biggest counterbalances forklifts trucks with a loading capacity of 5,000 kilos (3 units), 6,000 kilos (1 unit) and 7.000 kilos (1 unit) from gas28 to electric by the end of March 2023. With that, they will help save 107 tonnes of CO2 emissions29 per year and improve the working environment for colleagues.

Energy efficiency is an essential tool for achieving our net-zero operations target, but also delivering a great benefit for society. We can all be proud of energy efficiency initiatives we’ve carried out until now. With CEMP, we are taking it to the next level and making it future-fit.

Gözde Yilmaz Ozhamamci,

Director Site Sustainability, Facility & Real Estate Management (FREM)

Reducing transportation distances

Our Services Supply Network (SSN) is moving from a traditional centralised supply chain to a combined centralregional setup, decentralising shipping and focusing on reducing overall transportation distances, number of shipments and logistics, as well as handling activities. In 2022, as we started to roll out the new SSN, our spare parts distribution centres for USA & Canada (including packaging parts) and India were put in place which resulted in more than 500 tonnes of CO2 reduction30.

Reducing business travel related GHG emissions by 50% by 203031

Towards this goal, we reduced GHG emissions from business travel by 65% in 2022, compared to our 2019 baseline. Our global remote support operations launched in September 2022, has helped us avoid close to 100 tonnes of business travel CO2 emissions by solving customer issues remotely. In 2022, the number of site-based service engineers in the US and Canada, for example, increased by more than 25%, which led to a reduction of GHG emissions by around 158 tonnes CO2 e32.

Balancing remaining residual operational emissions

Our nature-based33 land restoration initiative, the Araucaria Conservation Programme in Brazil is set to work on the restoration of approximately 7,000 hectares of land in the Atlantic Forest by 2030, and includes potential certification of up to 13.7 million hectares under international voluntary carbon and biodiversity standards34 for carbon sequestration measurement35. The certification will measure carbon sequestration, meaning the project will support Tetra Pak’s commitment to achieving net-zero GHG emissions in its operations by 2030 by compensating remaining CO2 emissions.

Sold equipment

55% of our 2022 GHG emissions came from the equipment sold to and used by food and beverage manufacturers. We are therefore accelerating the development and deployment of processing and filling solutions with 50% fewer emissions per unit of production36, which can reduce the impacts of our customers’ production processes.

Reducing resources use and GHG emissions through upgrade and recovery solutions

In providing solutions and services that can help reduce energy consumption and emissions, Tetra Pak has facilitated more than 120 energy-saving and emission reduction improvement projects at customer sites and proposed more than 1,000 equipment upgrade solutions, thus effectively contributing to reducing carbon emissions in our customers’ operations since 2016. In 2022, we started a Sustainability Agile Development Programme. Under this programme, we have explored a way to reduce water and product loss through recovery solutions. We are also exploring a way to reduce GHG emissions on dairy ambient processing lines, as well as looking at integrating full scale decarbonisation in food plants. For this, our team engaged with solar thermal and high pressure and high lift heat pump experts.

Our complete portfolio of Expert Services can help optimise food safety and operational performance. Experts evaluate operational and environmental performance, as well as food safety and quality, and then identify exact challenges, losses and waste to be eliminated, striking a balance between performance, cost and risk. In 2022, in the America’s region, our portfolio of Expert Services helped 8 customers reduce CO2 emissions by 7.62 kilotonnes, which is equivalent to 9% of their total plant emissions37.

Learn more about what is next for Tetra Pak here.

1 Volumes exclude Blend in BIO (BiB) sold in Brazil. BiB is a mix of 75% LDPE and 25% plant-based LDPE

2 Based on climate accounting internal calculations (volume x emission factor) considering 72.7 kilo tonnes of plant-based plastic purchased in 2022. To calculate the avoided emissions number, we use a third-party emission factor for the plant-based polymers from public available lifecycle assessment by Braskem. Source: https://www.braskem.com.br/acv-studies

3 IPCC Report. Source: https://www.ipcc.ch/report/ar6/syr/downloads/press/IPCC_AR6_SYR_ PressRelease_en.pdf

4 Source: NOAA, NASA to announce 2022 global temperature, climate conditions | National Oceanic and Atmospheric Administration

5 Source: https://zerotracker.net/

6 Source: https://zerotracker.net/analysis/net-zero-stocktake-2022

7 Crippa, M. et al. (2021). Food systems are responsible for a third of global anthropogenic GHG emissions. Nature Food 2.3. Source: https://www.nature.com/articles/s43016-021-00225-9#citeas

8 Targets are considered ‘science-based’ if they are in line with what the latest climate science deems necessary to meet the goals of the Paris Agreement – limiting global warming to well below 2°C above pre-industrial levels and pursuing efforts to limit warming to 1.5°C. Source: https://sciencebasedtargets.org/how-it-works

9 Source: https://sciencebasedtargets.org/companies-taking-action

10 Our decarbonisation efforts focus on avoiding and mitigating GHG emissions correlated to our products and company, and carbon compensation to balance unavoidable residual emissions through nature-based solutions and other initiatives. Scope 1 and 2 GHG emissions combined were reduced by 27% compared to our 2019 baseline. Tetra Pak operations = Scopes 1, 2 and business travel, our value chain = Scopes 1, 2 and 3.

11 Scope 1 covers direct emissions from owned or controlled sources. Scope 2 covers indirect emissions from the generation of purchased electricity, steam, heating, and cooling consumed by the reporting company. Scope 3 includes all other indirect emissions that occur in a company’s value chain.

12 The target boundary includes land related emissions and removals from bioenergy feedstocks.

13 Scope 1 covers direct emissions from owned or controlled sources. Scope 2 covers indirect emissions from the generation of purchased electricity, steam, heating, and cooling consumed by the reporting company. Scope 3 includes all other indirect emissions that occur in a company’s value chain.

14 Scope 1 covers direct emissions from owned or controlled sources. Scope 2 covers indirect emissions from the generation of purchased electricity, steam, heating, and cooling consumed by the reporting company. Scope 3 includes all other indirect emissions that occur in a company’s value chain.

15 Source: https://sciencebasedtargets.org/companies-taking-action

16 UN News Global perspective Human stories: UN climate report: It’s ‘now or never’ to limit global warming to 1.5 degrees. Source: https://news.un.org/en/story/2022/04/1115452

17 Base materials are the materials we use to produce the packaging we sell to food and beverage producers, including paperboard, polymers, aluminium foil and inks.

18 Volumes exclude Blend in BIO (BiB) sold in Brazil. BiB is a mix of 75% LDPE and 25% plant-based LDPE

19 Based on climate accounting internal calculations (volume x emission factor) considering 72.7 kilo tonnes of plant-based plastic purchased in 2022. To calculate the avoided emissions number, we use a third-party emission factor for the plant-based polymers from public available lifecycle assessment by Braskem. Source: https://www.braskem.com.br/acv-studies

20 A one litre Tetra Pak carton package is typically made of approximately 70% paperboard, 25% of polyethylene and 5% of aluminium to protect the product inside.

21 For certain product categories, such as dairy products, the shelf life and food protection properties offered by the fibre-based barrier are comparable to aseptic carton packages that make use of aluminium.

22 Comparison between Tetra Pak carton packages

23 Comparison between Tetra Pak carton packages

24 Information about China’s carbon neutrality goals can be found at China maps path to carbon peak, neutrality under new development philosophy (www.gov.cn)

25 Savings for emissions and water are versus 2021 i.e., before the project was initiated, these reductions are for the Chakan site alone and the impact associated with removing the gas generators specifically.

26 The LEED Platinum certification is granted by the USGBC (United States Green Building Council), the most recent update of the LEED Sustainable Building Classification system. LEED provides a framework for healthy, efficient, carbon and cost-saving buildings and this is a globally recognised symbol of sustainability achievement. To achieve the LEED Platinum certification our project adhered to prerequisites and credits that address carbon, energy, water, waste, transportation, materials, health, and indoor environmental quality.

27 Fitwell Certification is a building certification system that provides guidelines on how to design and operate healthier buildings and encourage people to improve their eating methods and health behaviours. We are proud to be the first office in Panama to have this certification.

28 Liquified petroleum gas (LPG)

29 Calculated based on emissions from 6 counterbalances run on LPG vs. electric

30 Calculation is based on actual shipment history and is performed by the carriers. It is based on a 12-month cycle according to the shipment pattern. The reduction in CO2 emission is due to a reduction in kilometres and the change from air express to road freight since a new network structure has been setup.

31 2019 baseline

32 Calculations based on nine site-based service engineers not travelling, considering 80 flights per year, per person, and an average of 200 kg CO2 per flight (800 miles)

33 Solutions that are inspired and supported by nature, which are cost-effective, simultaneously provide environmental, social and economic benefits and help build resilience. Source: https://research-and-innovation.ec.europa.eu/research-area/environment/nature-based-solutions_en

34 Certification of the project will follow international voluntary carbon and biodiversity standards

35 The uptake and storage of carbon. Trees and plants, for example, absorb carbon dioxide, release the oxygen and store the carbon. Source: https://www.eea. europa.eu/help/glossary/eea-glossary/carbon-sequestration

36 Compared to 2019 for best practice lines

37 Combined CO2 emissions of all 8 customers in 2022.