Sustainable Supply Chains: How Lenovo Embeds ESG Principles Across Global Procurement Practices

Originally published in Lenovo's 2023/24 ESG Report

Supply chain ESG practices

As a global business offering a variety of products and services in 180 markets around the world, Lenovo manages a diverse and dynamic supply chain. Lenovo’s supply base is comprised of the following categories: internal manufacturing centers, production procurement, original design manufacturers (ODM), and general procurement. Production procurement includes all suppliers that provide materials or components that become part of Lenovo’s products. ODMs include manufacturing partners who manufacture products on behalf of Lenovo. General procurement includes all suppliers that provide materials and products which support Lenovo’s operations but do not become part of its products.

Lenovo’s supply base is comprised of multiple tiers in which lower tiers of suppliers provide materials and parts to higher tiers – and eventually to its Tier 1 suppliers, the suppliers with whom Lenovo has a direct contractual relationship.

The disclosures in Section 6.0 apply to Lenovo’s production procurement supplier base unless noted otherwise. The majority of Lenovo’s spend is with production procurement suppliers which often have ESG impacts and risks. Production procurement suppliers may pose social risks due to their reliance on significant labor forces, often drawing from extensive pools of lower-skilled workers who may be vulnerable to exploitation. Production procurement suppliers typically contribute to environmental impacts, encompassing factors such as energy, water, and materials required for production. The distribution of suppliers is restricted to production procurement suppliers, given their notable ESG risk profile.

Distribution of suppliers

Lenovo recognizes that there can be many benefits in utilizing local suppliers, including reduced logistics costs, potential decreases in GHG emissions, the opportunity to support local economies, and the preservation of community relationships. Lenovo considers local suppliers as those that operate in the same country as its significant locations of operations. In FY 2023/24, its significant locations of operations included manufacturing locations in China, US, Mexico, Brazil, Hungary, Japan, and India.

Lenovo estimates that 80 percent of production supply spend in China is with local suppliers. In other manufacturing countries or regions, Lenovo estimates that 20 percent of spend is with local suppliers.

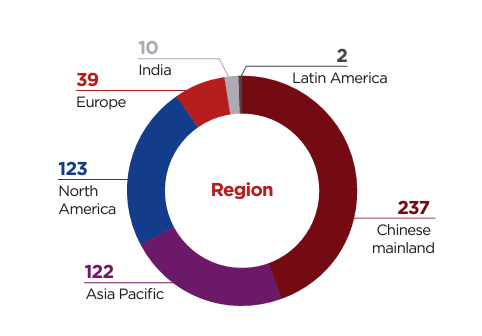

The chart1 above shows the geographic distribution of Lenovo’s 533 production procurement suppliers as of the end of 2023. Lenovo has identified all production procurement suppliers as critical suppliers and all the identified suppliers are included in the chart.

ESG in the supply chain

Lenovo is committed to sound ESG management across its end-to-end supply chain process. It has ESG-specific systems in place, supported by contractual requirements to help ensure that suppliers meet or exceed applicable labor, environmental, health and safety, and ethics standards. The practices disclosed in Section 6.0 align with Lenovo’s ESG-related internal corporate policies including:

- Lenovo’s environmental commitments which are codified in its Environmental Affairs Policy, Climate and Energy Policy, and Water Resiliency Policy, and

- Lenovo’s human rights commitments which are codified through its Human Rights Policy and further explained in its Anti-Slavery and Human Trafficking Statement.

Commitments that apply to its supply chain are extended to suppliers through its Supplier Code of Conduct.

Lenovo considers the supply chain a vital part of its operations and views effective supply chain management as an important contributor to its success. Given this, Lenovo has implemented a robust set of controls and programs to manage its overall procurement process.

Additionally, Lenovo recognizes that ESG risks and impacts exist among its suppliers which may differ from the ESG impacts and risks associated with Lenovo’s own operations. Lenovo implemented various practices to identify environmental and social risks along the supply chain and continue to monitor those efforts such as surveying new suppliers, performing ongoing supplier audits and assessments, and integrating several ESG-specific controls and practices into its Master Procurement Process.

Lenovo’s risk identification, practices, their implementation and monitoring are detailed throughout this section.

Master procurement process

Lenovo’s Master Procurement Process is designed to oversee all purchase commitments for production materials and the goods and services that support its worldwide operations. With a mission to deliver the best pricing, quality, supply, technology, and service in a sustainable manner, this model provides a controlled procurement approach that is applied across the organization for commodities, including the following elements for production procurement and general procurement:

- Delegation of authority

- Lenovo’s Code of Conduct includes requirements for the formal delegation which support accountability and responsible procurement practices. The ‘Authority to Make Lenovo Commitments’ section outlines the requirements for delegations with defined authority for commitments and other contract terms and conditions. Most importantly, it explicitly emphasizes that making business commitments outside these processes is not permitted.

- Supplier selection

- Implementing a controlled approach to awarding Lenovo’s business to suppliers is critical to meet its procurement objectives and to establish a trusted base of suppliers. Therefore, even the perception of favoritism or bias is unacceptable. To ensure business awards are conducted ethically and fairly, Lenovo has defined and approved sourcing methods to ensure the following:

- Suppliers have a fair opportunity to compete for Lenovo’s business

- Buyers conduct an ethical evaluation on carefully understood facts such as supplier prices, terms, and conditions

- The most capable suppliers are selected based on the best overall acquisition value

- Business awards are reviewed and approved with proper delegation of authority

- Implementing a controlled approach to awarding Lenovo’s business to suppliers is critical to meet its procurement objectives and to establish a trusted base of suppliers. Therefore, even the perception of favoritism or bias is unacceptable. To ensure business awards are conducted ethically and fairly, Lenovo has defined and approved sourcing methods to ensure the following:

- New supplier validation

- New suppliers are assessed for numerous capabilities including their operational aspects, financial stability, product or information security, and ESG performance. This assessment is facilitated through a supplier onboarding tool. More specifically, all new production procurement suppliers are assessed on their sustainability policies, codes of conduct, ISO certifications, ESG standards, environmental impact aspects, controls to prevent forced labor, and public reporting. Of particular concern are suppliers that may be listed as restricted or denied parties identified by governments and/or international agencies. Lenovo’s policy and formal practice is that under no circumstances shall Lenovo’s personnel purchase, sell, or ship any product contrary to applicable export laws or to any individual or firm appearing in any relevant government list of any party who has been denied export or import privileges.

- During FY 2023/24, 169 production procurement suppliers were assessed using this process.

- Contract management

- Supplier relationships are best managed when there are clear stipulations of responsibilities, deliverables, and relevant terms and conditions. Lenovo’s supplier contracts incorporate legal and operational agreements and address various types of engagement. Additionally, all suppliers must comply with Lenovo’s Supplier Code of Conduct, in which they are required to comply with the latest version of Responsible Business Alliance’s (RBA) Code of Conduct as well.

- There are multiple code elements and requirements under the Supplier Code of Conduct relating to environmental, labor, and human rights matters. Instead of asking suppliers to sign separate Supplier Code of Conduct contract one by one, their compliance with the comprehensive Supplier Code of Conduct is executed via Lenovo’s standard purchase agreements or standard purchase orders. To ensure all target agreements include clauses on the Supplier Code of Conduct, the continuous monitoring is in place, including the accessibility check of related links. Lenovo’s Supplier Code of Conduct and the RBA Code of Conduct strictly prohibit bribery and corruption. The RBA audit protocol also includes consideration of anti-bribery and anti-corruption.

- Supplier performance evaluation

- Supplier performance evaluation is to provide timely feedback to suppliers to improve performance, move business volume to best suppliers, to reduce or eliminate business to poor performing suppliers. Performance management includes key criteria such as cost, quality, supply, technology, service and ESG as deemed appropriate.

In addition, Lenovo has implemented practices used to promote environmentally preferable products and services when selecting suppliers including validating new suppliers and evaluating suppliers based on ESG considerations. Ongoing monitoring of supplier management efforts include audits of suppliers’ relevant ESG performance and third party ESG ratings. The master procurement process continues to reinforce ESG as a criterion in supplier selection.

Internal training

To ensure those with delegated authority are informed on ESG best practices, Lenovo conducts comprehensive communication and education activities throughout the year for its global supply chain team. In FY 2023/24, Lenovo enhanced the global supply chain ESG education program by holding additional live training sessions in multiple ESG areas to help the procurement team build on knowledge and skills. Offered in both Chinese and English, the overall attendance in those training sessions reached 2,009. In addition, Lenovo provides compulsory ESG courses and required a 100 percent completion rate with the production procurement team. Procurement team were also surveyed on their understanding of ESG so improvements can be monitored annually.

| Education module | Training sessions/courses |

| ESG Overall |

|

| ESG Focus |

|

1The allocation chart based on the registered legal entity of the headquarters of suppliers. No significant change in data or calculation methodology compared with previous year.