A Perfect Fit: How 3D Printing Is Shaping a New Era of Customized Care

From insoles for foot pain to casts and splints, 3D-printed devices are making one-size-fits-all healthcare a thing of the past.

By Jackie Snow

When you think about the possibilities 3D printing brings to healthcare — things like bioprinted organs and a custom mix of medications printed in a single pill — it sounds straight out of science fiction.

Custom-printed kidneys or personalized pills may not be available just yet, but 3D printing is already improving healthcare for people, particularly in the fields of prosthetics and orthotics, devices worn on the body to help correct structural issues or provide support. 3D printing gives healthcare professionals the ability to tailor these devices to fit individual patients, resulting in improved comfort and a better experience.

“3D printing excels at personalization and customization,” says Philipp Jung, global head of orthotic solutions at HP, and general manager of Arize, HP’s new orthotics solution. “And there’s nothing more personal than the human body.”

The market for personalized orthotics, prosthetics, and related custom health and wellness solutions is nearly $10 billion, according to HP research. From sockets for prosthetic limbs to helmets for newborns to casts for broken bones, the ability to create one-of-a-kind products at scale with 3D printing — also known as mass personalization — is transforming healthcare to be more precise, relevant, and responsive to individual needs.

“3D printing has offered us a freedom to design and manufacture,” says Deepak Kalaskar, an associate professor in the Department of Orthopedic and Musculoskeletal Science at University College London, with expertise in biomedical engineering. “We are currently very much at the infancy of 3D printing, but that’s not stopping anyone from thinking about how we are going to use this revolutionizing technology.”

Pain relief through personalization

More than three-quarters of Americans will experience foot pain at some point in their lives, according to the American Podiatric Medical Association. Arize Orthotic Solution, an end-to-end digital solution developed with HP technology, is designed to relieve some of that pain with better-fitting, 3D-printed custom orthotics.

Using Arize, doctors can capture an image of a patient's foot with a scanner in as little as two minutes. From there, the software lets the doctor review the foot’s scan, choose and customize an insole, and send the order to a 3D-printing facility. When the insoles eventually wear out or if the patient wants a pair of orthotics for a different style of shoe, the same measurements can be used to reorder, saving the patient another trip.

“It’s a more efficient process,” says Gavin Ripp, a podiatrist who’s been using Arize at Premier Podiatry & Orthopedics, in the Sacramento, California, area. “We’re able to get devices back quicker, and they are easy to replicate.”

The new process is not only more precise, it also results in a lower-profile, less clunky device.

“Patients are really liking that they can put them into a wider variety of shoes than what was possible before,” Ripp says.

Better fitting casts and splints

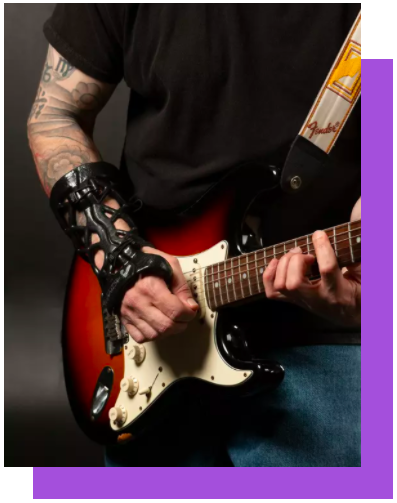

For injuries that require immobilization of part of the body, ActivArmor is the first and only provider of 3D-printed casts and splints, with products for feet, ankles, legs, arms, hands, wrists, and fingers. Besides being custom fit, the casts are waterproof, breathable, and hygienic so the user can bathe like normal. The shell-like structure reveals the skin underneath without reducing strength and durability.

“In a traditional cast, you can only see at the two ends of the cast — everything inside, including movement, is hidden,” says Diana Hall, CEO of ActivArmor. “With ActivArmor, you can see and make adjustments throughout the course of healing, which improves outcomes.

Doctors use a free iPhone app to scan the affected body part for measurements and get a custom-fitted cast within a few days. It can be ordered locked-on for compliance, or easily removable per doctor’s orders.

ActivArmor recently launched a 3D-printed walking boot, which is waterproof, lighter, and more breathable than other orthopedic boots, with the bonus of being custom-designed for each patient’s unique injury or condition.

“There is no one-size-fits-all solution for immobilization,” Hall says. “3D printing allows for patient-specific medicine, with every device custom designed and made for a patient’s unique injury, treatment, and lifestyle.”

A more comfortable device for growing babies

The malleability of a newborn’s skull means the shape of an infant’s head is sometimes made uneven while passing through the birth canal or can develop lopsided changes from lying a certain way too long. More than 3% of newborns have severe or very severe head shape deformity, with up to 50% experiencing a mild or medium deformity. Doctors often turn to orthotic treatment using a helmet to gently reshape the head.

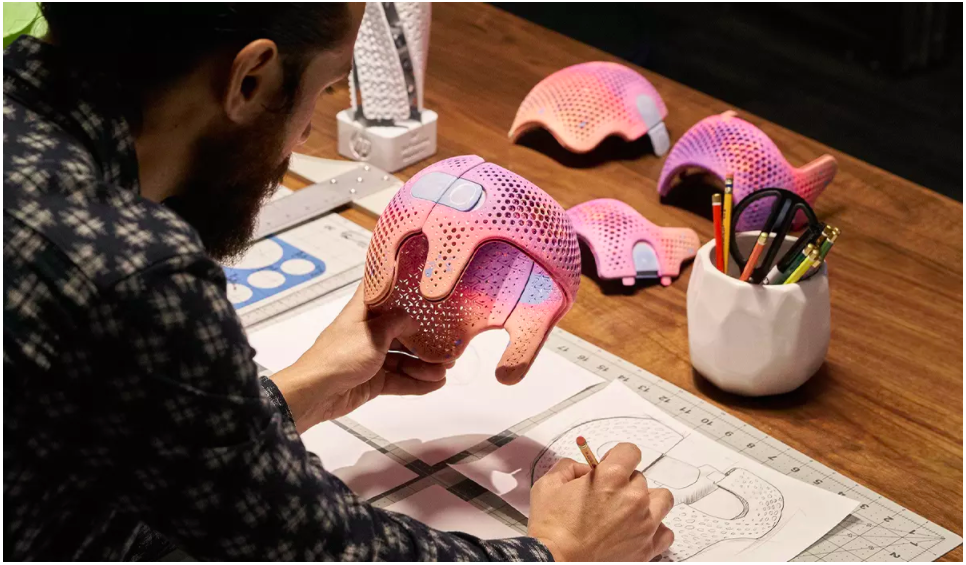

Traditionally, those helmets were made by re-creating the head shape carved in foam and then building the device around it, a time-consuming process that only got close to a good fit. Healthcare technology company Invent Medical devised a better way, with a solution called Talee, a cranial 3D-printed helmet that has helped babies in 30 countries already.

“3D printing represents the opportunity of not just how to change the product, but even the process of how the babies are treated,” says Jiří Rosicky, Invent Medical’s CEO.

HP Multi Jet Fusion 3D printing reduces the time it takes to create a helmet by half. The more breathable form and perforated structure can be made with lighter material, which makes the helmet more comfortable for the baby, even in the summertime when parents might be tempted to take it off to help with the heat. Rosicky says even offering a variety of colors has helped parents deal with the societal pressure of drawing unwanted attention to their baby.

“From the point of view of clinical specialists, aesthetics has a lower priority than function, but it’s very important for parents,” Rosicky says. “How you feel about a product is tied into how the treatment is accepted, and if you are more confident in the treatment process, it really helps."

Customizing sockets for prosthetic limbs

After an accident in 2009 that resulted in his legs being amputated, Chris Hutchison felt lucky to be alive. Adjusting to the prosthetics he used to get around was an added stress in an already trying time. The socket that was the critical interface between his residual limb and the rest of the prosthetic had to be sculpted by hand. Chris used a wheelchair while it took multiple trips over several weeks to get the right fit. Even then, the socket was uncomfortable and even painful at times.

Alan Hutchison, Chris’s father and an engineer by training, wanted something better for his son. The father-and-son team started Prosfit in 2014, a company that uses HP’s Multi Jet Fusion 3D printing to make better-fitting sockets more quickly, so others don’t have to go through what Chris did. According to a World Health Organization report, more than 35 million people around the world are in need of prosthetics or orthotics, but only one in 10 has access to or can afford the devices they need.

By digitizing the process of designing, fitting, and manufacturing a prosthetic socket, ProsFit has reduced the time it takes to make and deliver a socket from weeks to days, and with far fewer steps, lowering the cost and making the process more convenient for patients. The final sockets can now be made and fitted in only two visits and cost 25% less than the handmade ones.

“Our vision is a world where innovation provides limb wearers a choice of affordable, reliable, and desirable prosthetic products and services,” Alan Hutchison says. “Digital technologies including 3D printing make this possible.”