Maintaining the Mission

Team members from around the system came together to support American’s Civil Reserve Air Fleet (CRAF) activation these past few weeks. Throughout our airline, so many aviation professionals have raised their hands to help, including our Technical Operations team. So often behind the scenes, this group is charged with maintaining the safety of every aircraft in the air and keeping our airline moving. The same is the case for our CRAF flights. But there are differences, and our Tech Ops team has stepped up in a big way to ensure the safety and success of every mission.

In the air and on the ground

In addition to a full inspection before departure, each aircraft leaving the U.S. to begin a mission has two or more JFK- or PHL-based aviation maintenance technicians (AMTs) on board should any maintenance-related needs arise. It’s a voluntary position and one for which the team has overwhelmingly raised their hands to support. “Seeing everyone else doing their part, I wanted to do my part of it, too,” said JFK-based AMT Philip Chu who recently returned from a mission.

Our U.S.-based AMTs also team up with our Frankfurt, Germany (FRA)-based AMTs who have been traveling to the various military bases where our missions depart from to provide on-the-ground support, including completing full inspections prior to the flight, supporting fueling operations and loading evacuees’ luggage and personal belongings.

“Working with our Frankfurt team, we completed a maintenance check of the aircraft before it departed the military base,” said JFK-based AMT Neftaly Bayon, who quickly volunteered to be part of these missions. “When I was doing a walkaround of the aircraft, I saw a little girl who reminded me of my daughters when they were young. She was so happy, waving to everyone. I would do it again.”

Back at home

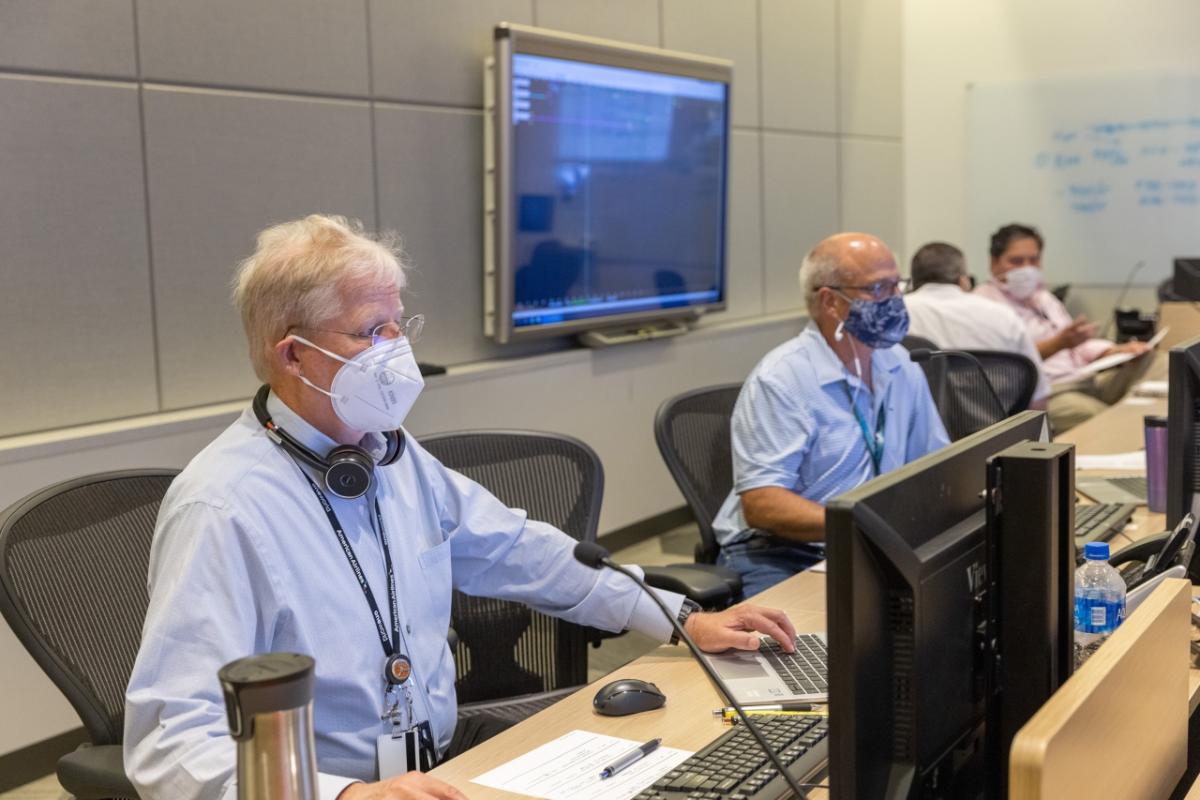

Supporting these missions and deploying our Tech Ops resources starts with the team behind the team. Our Maintenance Operations Control (MOC), Routing and Supply Chain teams have been working around the clock to prepare and position aircraft and resources and coordinate with departments across the airline who are supporting these important flights.

So many have stepped up in a big way, including engineers who have created protocols and authorizations for configuring aircraft, and maintenance control technicians who organize any maintenance needed to prepare the aircraft.

The MOC team manages the fleet and the maintenance side of the operation and coordinates across the airline to supply maintenance support — that work involves more moving pieces for the CRAF flights. “The CRAF missions are dynamic. That’s why our MOC team mans the IOC Command Center around the clock, continuing to coordinate with the other departments to manage any obstacles, which may present themselves,” said John Richter, Senior Manager of MOC.

The Materials, Supply and Aircraft on Ground (AOG) teams worked to ensure these missions had the proper materials to keep moving seamlessly. We’re flying to new destinations where we don’t have our usual support — be it parts, tools or people — which is why it’s critical that each aircraft is loaded with a fly away kit. They contain all the necessary tools and parts to address any issues with an aircraft. “The entire Supply Chain organization really stepped up to support our passengers and crew by ensuring the safety and dependability of every flight,” said Matt Flock, Senior Manager of Planning.