Investing Across the Value Chain in Circular Solutions for Old Mattresses

What if instead of going to the landfill, your old mattress was recycled to find a second life in something new, like a sofa? By turning end-of-life mattresses into RENUVA™ polyols for use in new furniture and bedding, our RENUVA™ Mattress Recycling Program is contributing to both a circular and lower-carbon economy.

But Dow isn’t doing it alone. Collecting and recycling old mattresses into new polyols is a complex process, and we’ve engaged the entire value chain – from recyclers to materials manufacturers to brand owners – to make it happen.

“This project represents a fully circular investment across the value chain highlighting Dow’s materials science solutions to critical challenges facing the industry,” said Marcel Moeller, Global Sustainability Director, Dow Polyurethanes.

Here’s a look at the RENUVA™ Mattress Recycling Program and its benefits:

The Issue

In Europe, each year approximately 40 million discarded mattresses end up either as bulky waste in landfills or are incinerated to produce heat and electricity. However, incineration is a source of carbon dioxide (CO2) and a waste of valuable resources.

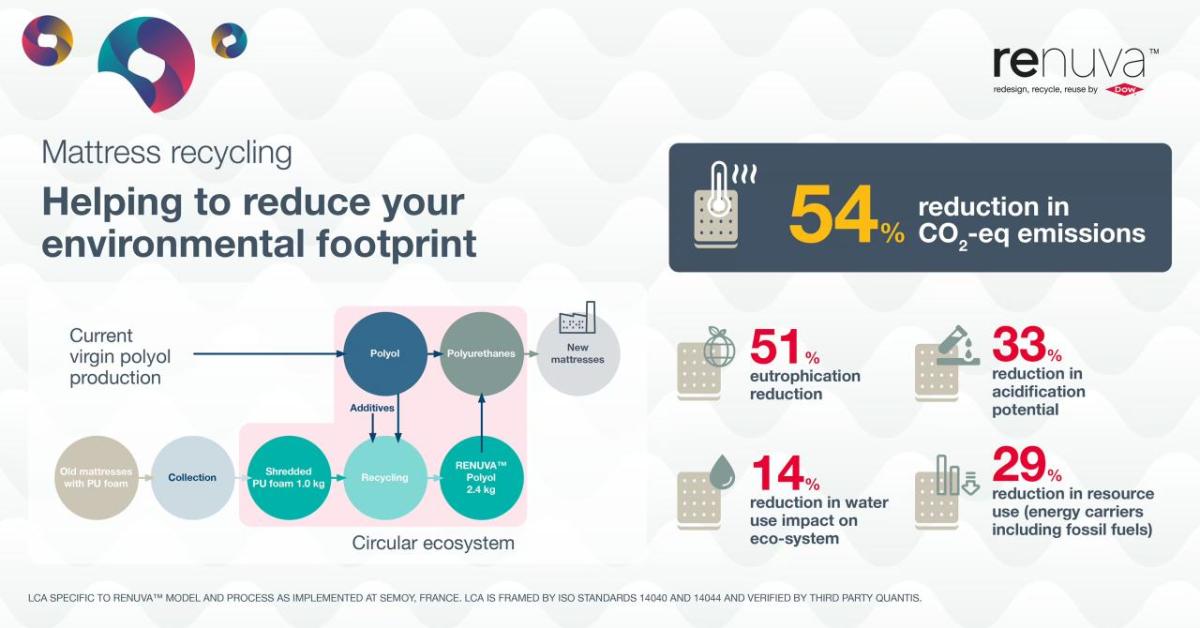

But by breaking down the foam into its base molecules through advanced processes that Dow uses to make RENUVA™ polyols, discarded mattresses stay out of the waste stream, and non-renewable resources that would have been used to make virgin products are saved.

In 2021, a cradle-to-gate ISO-certified external life cycle analysis study demonstrated that RENUVA™ polyols offer the potential for a significant reduction of the environmental footprint, resulting in a 54% equivalent CO2 reduction compared to standard polyol production.

Collaborating Across the Value Chain

To bring new value to old mattresses, the RENUVA™ Program brings the value chain together to create a new business ecosystem model. The collaboration started between Dow, the raw material producer and supplier, and H&S Anlagentechnik, the technology provider. Ecomaison supplies the polyurethane foam from dismantled post-consumer mattresses for the recycling unit. Orrion Chemicals Orgaform is Dow’s manufacturing partner and produces the RENUVA™ polyol for Dow. The Vita Group, Europe’s leading flexible polyurethane foam manufacturer, was the first customer to use the first batch of RENUVA™ polyol in their newly launched ORBIS foam, which replaces up to 30% of virgin polyol with RENUVA™ polyol.

Turning a Concept into a Reality

Construction of the first commercial RENUVA™ production plant started in early 2021. The RENUVA™ plant has the capacity to process the foam from 200,000 waste mattresses, avoiding these being incinerated or landfilled every year.

The plant was inaugurated in France in September 2021. In March 2022, the first sofa containing ORBIS foam and RENUVA™ polyol was commercialized in France. The RENUVA™ polyols are now being promoted to other key bedding and furniture customers in Europe as well.

“This program is part of Dow’s strong commitment to delivering solutions that help close the loop and protect our environment,” Moeller said.