Environmental Sustainability Drives Operational Excellence

Originally published in Quest Diagnostics 2021 Corporate Responsibility Report

The COVID-19 pandemic had a dramatic impact on our operations, including our testing mix, which affected our environmental metrics. As Quest transitions to the post-pandemic period, we anticipate that there will be additional impacts and we will remain focused on sustainability considerations.

Key elements driving our environmental sustainability program

- Pollution prevention: We will minimize waste in our operations through process improvements and focused recycling efforts

- Energy efficiency, sourcing and use: We will include renewable energy in our sourcing of energy when cost-effective and feasible. We will use energy efficiently and make efforts to improve efficiency through technology and innovation

- Fleet conservation: We will utilize technology to improve our ground fleet efficiency, thereby reducing carbon fuel use and associated greenhouse gas emissions (GHG)

- Strategic sourcing: We will take environmental impact into consideration when making decisions about the materials and services we purchase in order to reduce consumption of natural resources and decrease waste and emissions

Our Environment, Health, and Safety (EHS) department leads the development of our strategic environmental plans and GreenQuest, working closely with regional teams to identify opportunities for improvements and to lead local projects. We maintain programs to monitor the environmental impacts at our major laboratories and audit environmental management. We train key staff in environmental management, covering handling of chemicals, pathogens, and waste reduction, and include localized training in the specifics of each facility. We continue to pursue ISO 14001 and ISO 22301 certifications in 2022 for our San Juan Capistrano laboratory, and we are also pursuing LEED-equivalent certification for our new Clifton laboratory.

Climate action

In 2021, we started the process of analyzing climate risks and opportunities for our business based on the recommendations of the Task Force for Climate Related Financial Disclosures. We created teams to review our climate risks and opportunities, as well as our water use and waste. We also initiated efforts to improve measurement of our GHG emissions, with a focus on Scopes 1 and 2.

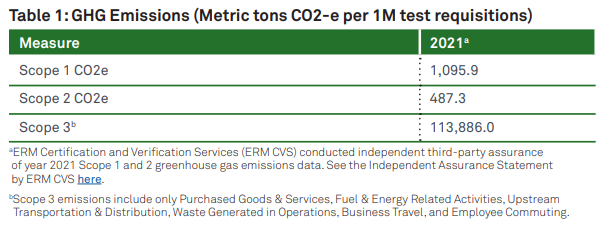

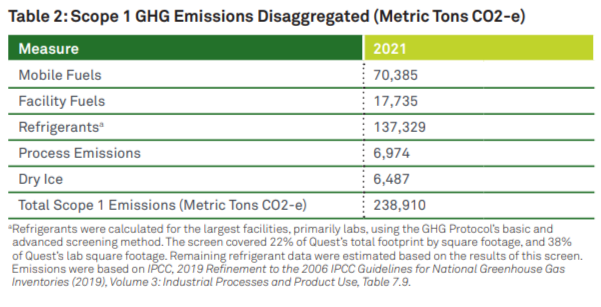

Data in the following tables include estimates. US EIA’s Commercial Building Energy Consumption Surveys (CBECS) data and EPA’s Emissions & Generation Resource Integrated Database (eGrid) were used to estimate utility usage and related emissions factors for small locations when not available from other sources. These data cover 100% of our operations in North America and Latin America.

To date, our efforts to reduce our GHG emissions have included energy efficiency measures at our facilities, such as laboratory testing platform consolidations, LED lighting retrofits, purchase of green power, and route optimization, including the following key accomplishments in 2021:

- Completed the consolidation of the majority of our East Region lab operations into our Clifton, NJ lab

- LED lighting retrofits which we believe will reduce our overall electricity consumption by 59% in our Marlborough cytology lab

- Reduction of 1.2M miles in driving through route optimization projects for our fleet, which we believe will result in reduction of 424 metric tons of CO2 emissions

- Quest continues to qualify for the EPA’s Green Power Partnership by exceeding 7% renewable energy use.

Fleet conservation is another key aspect of our efforts to reduce GHG emissions, which we estimate resulted in a reduction of 1.8 billion pounds of CO2 and the elimination of more than 1,100 surplus vehicles in the last 15 years.

Electric vehicles

We are considering electric vehicles for our fleet. In 2021, we began the development of an electric vehicle pilot project. At our lab in Clifton, NJ, we installed charging stations in the public area of the garage. We are building out charging infrastructure at out Marlborough, MA lab and plan to begin infrastructure design and construction at remaining pilot locations.

A Gold Rating in India

Our office facilities in India achieved a Gold Rating from the India Green Building Council, which encourages green concepts and techniques to address national priorities in India. The rating considers site and facility management, water efficiency, energy efficiency, health and comfort, and innovation.

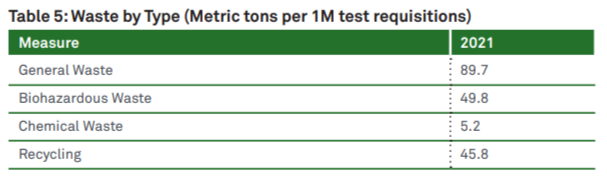

Waste reduction

Quest works with suppliers to find products and processes that can minimize waste across our operations. In 2021, several of our facilities completed new waste management projects which we believe reduced hazardous waste or landfill waste, such as:

- Our Las Vegas facility eliminated pH wastewater disposal, thus reducing hazardous waste generation by 285,000 lbs

- At our West Hills, CA and Sacramento, CA labs, all paperwork was required to be recycled, reducing our future annual landfill waste by 210,000 lbs

- Cleveland HeartLab™ began recycling and reusing Styrofoam shipping containers

- Specimen cup and stool container redesigns, among other changes, reduced Quest’s plastic waste by 105 tons in 2021, for a total of 407 tons saved since the project initiated in 2018

- Reduced the amount of paper waste in our PSCs by an additional 270 tons in 2021, for a total of 546 tons saved since the project initiated in 2018

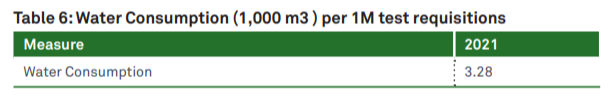

Water reduction

Our facilities continue to look for creative ways to reduce water consumption. Overall, in 2021, we reduced our water consumption by 16%.

- In California, several of our logistics hubs transitioned to waterless fleet vehicle washing, which we estimate will save 32,490 gallons of water per year

- At the Las Vegas facility, a 310 linear-foot planter was removed to reduce water used to maintain plants, which we estimate will save 164,250 gallons of water

- At Cleveland HeartLab, all toilets are now fitted with water-saving flushers

- In the Dallas lab facility, all urinals were replaced with flushless units

Occupational health and safety

The Quest Diagnostics EHS team believes our critical business objectives include workplace safety; the health of our em ployees, contractors, and others working in our facilities; and the protection of the environment. We are committed to proactively managing workplace safety to eliminate risks and hazards as well as ensure regulatory compliance. In 2021, we invested in safety data management software which will allow us to improve performance, gain insight, and drive compliance. Our safety management system aligns with ISO 45001 and ANSI Z10 elements by:

- Creating regional/business unit strategic plans that review current metrics, evaluate and develop EHS programs, identify opportunities to reduce workplace injuries, address trends, mitigate risks, generate action plans for identified risks and professional development of our EHS professionals

- Periodically conducting internal audits at all facilities • Encouraging employee engagement in safety committees

- Requiring employees to review and acknowledge job hazard analyses

- Providing monthly job-specific safety training to employees through the company’s learning management system