Decarbonization Strategy at Novelis

Originally published in Scaling Circularity: Novelis 2023 Sustainability Report

Aluminum is a robust and durable material ideal for creating everyday items from beverage cans to cars, buildings, and aircraft. Among its core properties, aluminum is infinitely recyclable with no loss in quality during remelting and re-processing. Additionally, recycled aluminum uses approximately 95% less energy than is required to produce primary aluminum from mining and smelting, with a nearly equivalent reduction in greenhouse gas (GHG) emissions. Because recycled aluminum’s carbon footprint is significantly less than primary aluminum, we can continue to reduce our emissions by recycling more aluminum scrap than we do today.

By scaling circularity across our value chain, we can deliver lower-carbon products to our customers.

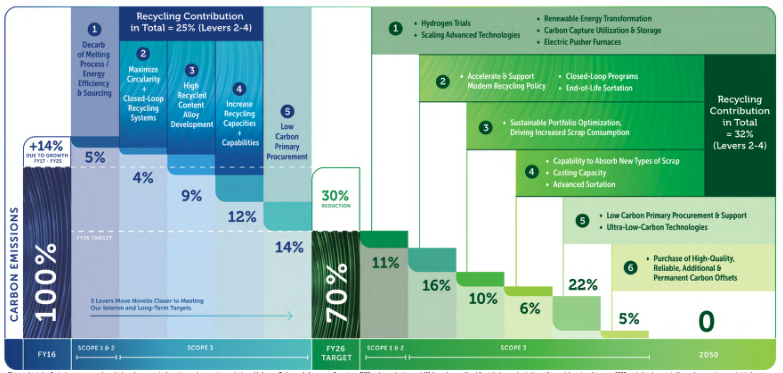

The following sections describe our decarbonization strategy and our implementation progress over the last fiscal year on our journey to achieve our 2026 targets. Collaborating across our value chain will help us achieve our 2050 carbon neutrality goal.

Lever 1: Decarbonizing the Melting Process and Energy Sources

Lever 1 covers our Scope 1 and Scope 2 GHG emissions. Our Scope 1 emissions come from the energy we consume at our operations and represent 8% of our total emissions. Scope 2 indirect emissions come from the energy we source from utilities, which is 5% of our total emissions.

Aluminum recycling — specifically, remelting — is the most energy intensive process in our operations. We make efforts to increase efficiencies in our plants to reduce fuel and energy use. We seek to decarbonize the melting process through alternative fuels, clean energy sources, and innovative carbon capture technologies.

Lever 2: Maximizing Circularity (Increasing Recycled Content)

Creating a circular aluminum value chain is a critical pathway to decarbonizing our industry.

Decarbonization Levers 2 through 5 are focused on reducing our Scope 3 emissions, which account for 87% of our carbon footprint.

We are focused on innovating and scaling the benefits of a low-carbon and circular economy for our business and partners along our value chain. We take a multi-pronged approach to circularity by collaborating with the most innovative partners in the value chain.

While we operate in a complex and changing environment, Novelis is well-positioned to lead.

Lever 3: Innovating New High-Recycled-Content Alloys

Novelis is a leader in aluminum recycling. As such, we achieved an average recycled content in our products of 61% in FY23. The recycled content of our can sheet — our most extensive product line — exceeds 80%. To increase circularity and decrease the carbon footprint of all our products, we work closely with customers in all four of our value streams (beverage packaging, automotive, aerospace and specialties) to develop high-recycledcontent alloys that meet their complex technical specifications and requirements.

Lever 4: Increasing Recycling Capacities and Capabilities

By increasing recycling and casting capacity, we can produce our own ingots with higher amounts of recycled material, which reduces the need for higher carbon primary aluminum.

As a result of our investments, shown on page 22, we achieved an average of 61% recycled content in our products in FY23. Last fiscal year, we purchased or tolled approximately 2,325kt of recycled metal, including more than 82 billion used beverage cans. We view recycling as the hallmark of our business and a cornerstone of our decarbonization efforts. We look for opportunities to improve our aluminum scrap intake and processes to transform scrap aluminum into new high-value products. Since 2011, we have completed or announced approximately $2 billion in recycling investments.

Lever 5: Supporting Decarbonization of Primary Aluminum

We explore opportunities to increase the amount of recycled content in our products but are limited by factors like scrap availability, the quality of scrap mixes, and customer requirements. To supplement our use of recycled content, we also purchase primary aluminum, with the aim to secure the lowest-carbon primary aluminum available. Low-carbon primary aluminum is mainly produced using renewable energy (primarily hydropower) for the smelting process. The availability of lowcarbon energy sources varies by region.

While we strive to purchase the lowest-carbon primary aluminum available, only about 25% of the 69,000kt of primary aluminum produced globally each year is low carbon, limiting our ability to purchase from low-carbon sources. Ultimately, the primary aluminum industry requires transitioning from high-carbon energy sources (e.g., those powered by coal) to renewable sources to decarbonize the energy-intensive smelting process.