Cummins Moves Forward on Spanish Plant Making Technology Key to 'Green' Hydrogen Production

Global power leader Cummins Inc. will soon begin building its new gigawatt electrolyzer manufacturing plant in Guadalajara, Castilla-La Mancha, Spain, reaffirming the company’s commitment to play a key role in expanding the green hydrogen economy in Europe and globally.

Last year, Cummins announced it had selected Spain as the site of a new proton exchange membrane (PEM) electrolyzer plant. Earlier this year, the company purchased more than 530,000 square feet (50,000 square meters) of land in the industrial area of Guadalajara, Castilla-La Mancha, where it is now preparing to begin construction.

“We’re excited to be a part of Guadalajara and put down our roots in Spain,” said Amy Davis, Vice President and President of New Power at Cummins. “The growing hydrogen economy here continues to be an attractive environment for Cummins to increase its global electrolyzer manufacturing footprint.

“With the support of the Spanish government and European Union, Spain’s hydrogen market has great potential,” she added. “This facility will poise Cummins to help European customers transition their energy supply and meet ambitious sustainability goals. This plant is also another step toward achieving Cummins’ own carbon neutrality targets.”

Construction of the new PEM electrolyzer plant is anticipated to be complete at the end of 2023. It will initially create approximately 150 high-skill jobs, with the potential to add another 200 jobs as production grows. The more than 200,000 square foot (20,000 square meters) facility will include system assembly and testing and have the capacity to produce 500MW of electrolyzers per year, scalable to more than 1GW per year.

Cummins’ investment in Spain adds to the company’s global efforts to scale development and manufacturing of zero-emissions technologies and ultimately reduce carbon emissions. The company also recently announced the expansion of PEM electrolyzer manufacturing capacity at its Oevel, Belgium, factory to 1GW.

“Green” hydrogen – produced through water electrolysis using renewable electricity – is a key enabler to economy-wide decarbonization. Once produced, hydrogen can be stored as a liquid or a gas and transported. As an alternative to fossil fuels, hydrogen is a viable zero-emissions solution for some of the world’s most energy intensive and hardest-to-abate sectors, such as heavy-duty commercial transportation, manufacturing, industrial processes and chemical production.

“By increasing our ability to meet demand for hydrogen generation technology, this facility will help accelerate the global clean energy transition and the role of hydrogen as a viable alternative energy source in Europe,” said Alexey Ustinov, Vice President of Electrolyzers at Cummins. “Cummins is committed to helping the European Union produce more hydrogen domestically, reducing dependence on fossil fuels and securing a sustainable future.”

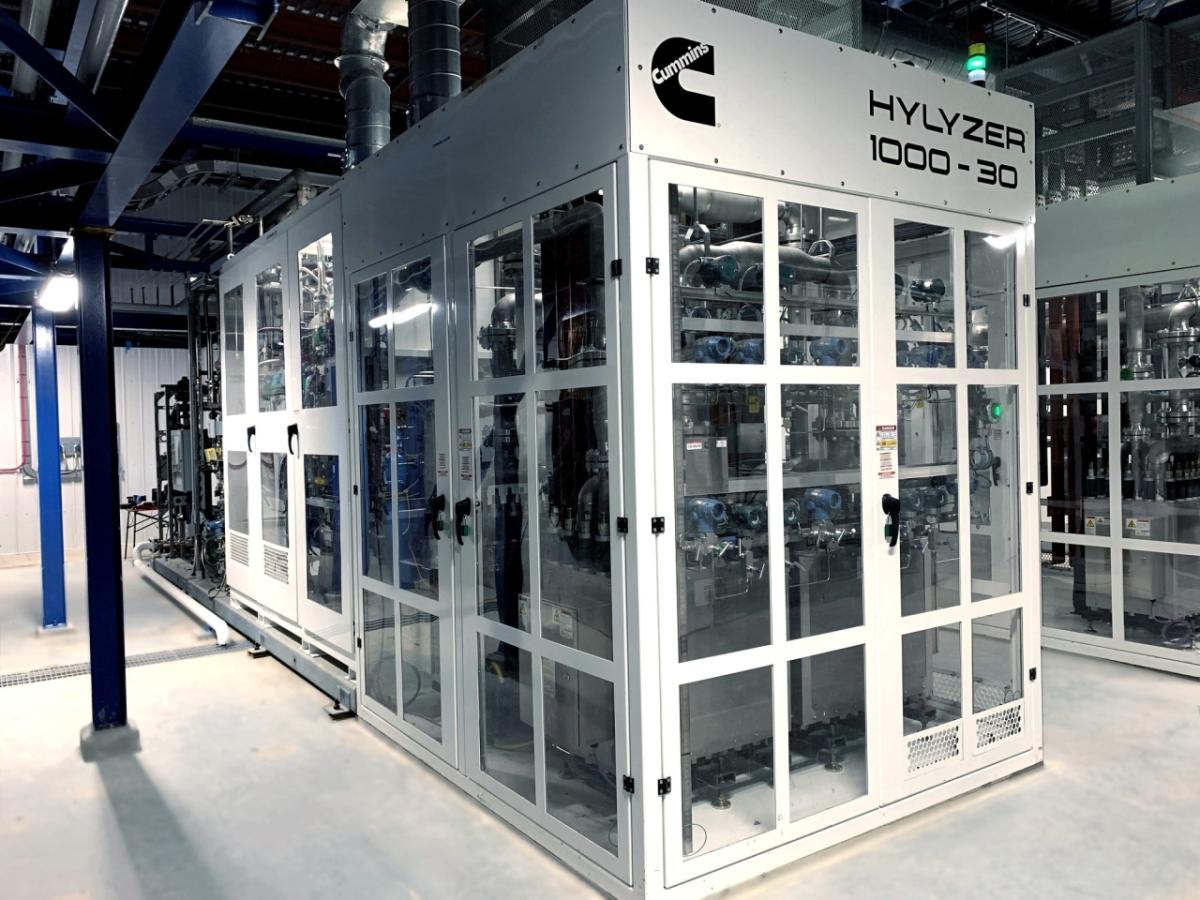

Cummins has a long history of advanced technology and engineering capabilities and innovates across a broad portfolio of market-leading renewable hydrogen technologies.

The company has been part of many of the world’s hydrogen “firsts,” including powering the world’s largest PEM electrolyzer in operation at 20MW in Bécancour, Canada; the world’s first megawatt-scale demonstration plant for storing wind energy in the natural gas grid in Windgas Falkenhagen, Germany; the world’s first 100% hydrogen-powered passenger train fleet in Lower Saxony, Germany; and the world’s first hydrogen refueling station for ships, cars, trucks and industrial customers in Antwerp, Belgium.

END