3D-Printed Furniture Gives E-Waste Plastics a Second Life at Lenovo Tech World

Aectual, a leader in industrial 3D-printing, used recycled device components from Lenovo to create furniture for the event in Austin, Texas

During Lenovo’s annual Tech World event, attendees took breaks from the bustle to discuss visions about the frontiers of AI while sitting on low, padded stools. These poufs—with red tops evocative of the iconic TrackPoint—had surprising origins. Text emblazoned on one read: “You’re sitting on a server.” But it’s a pouf, right? In this instance, thanks to ingenious 3D printing and recycling efforts of e-waste plastics from a mix of devices, both can be true.

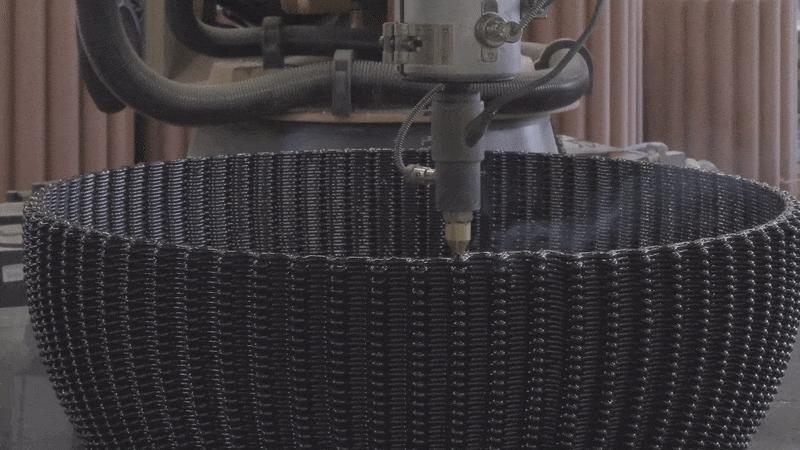

Lenovo, the global technology powerhouse, collaborated with Aectual, the Netherlands-based leader in 3D printing for architecture and interior design, to bring the concepts of asset recovery and circularity to life.

“Who would have imagined e-waste plastics transforming into 3D-printed event furniture?” said Claudia Contreras, Executive Director of Global Sustainability Services at Lenovo. “I love discovering new, exciting ways to deliver on Lenovo’s commitment to sustainability, and it’s a real joy to have such an inventive and ambitious partner in Aectual.”

The collaboration goes much deeper than recycling e-waste plastics from servers, laptops, or mobile phones. Lenovo workstations have powered innovative construction processes and helped create more sustainable tradeshow experiences.

“Aectual and Lenovo share an intense commitment to meaningful innovation,” said Hedwig Heinsman, Cofounder and Creative Director at Aectual, which offers design-to-delivery of everything from flooring to fixtures. “Here, we pushed each other to give recovered materials a new life, create something surprising, and prioritize sustainability, which is one of our core values. I’m thrilled to see the results exhibited at Tech World and look forward to what we imagine and build together next.”

The Aectual process, which prioritizes circularity, can take back a product after use, shred the material, and reuse it in new 3D-printed products up to seven times.

The poufs at Lenovo Tech World offer one small example of the type of recycling that can be possible through solutions like Lenovo’s Asset Recovery Services (ARS), an end-to-end solution to minimize e-waste through secure device lifecycle management. Since 2005, Lenovo has processed nearly 800 million pounds of Lenovo-owned and customer-returned computer equipment1.

Asset recovery is one piece of a wider investment in sustainability, including Lenovo’s commitment to reaching net-zero greenhouse gas emissions by 2050. With ongoing changes from supply chain operations to energy generation, it’s rare to see something so tangible—and certainly so sittable—as the Tech World poufs.